Mortars and recoilless rifles. Experience in the combat use of mortars Flight range of mines from a mortar 80 mm

Artillery of Russia and the world, guns photos, videos, pictures watch online, along with other states, introduced the most significant innovations - the transformation of a smooth-bore gun, loaded from the muzzle, into a rifled gun, loaded from the breech (lock). The use of streamlined projectiles and various types of fuses with adjustable settings for the response time; more powerful propellants such as cordite, which appeared in Britain before the First World War; the development of rolling systems, which made it possible to increase the rate of fire and relieved the gun crew from the hard work of rolling into the firing position after each shot; connection in one assembly of a projectile, propellant charge and fuse; the use of shrapnel shells, which, after the explosion, scatter small steel particles in all directions.

Russian artillery, capable of firing large shells, acutely highlighted the problem of weapon durability. In 1854, during the Crimean War, Sir William Armstrong, a British hydraulic engineer, proposed a method of scooping wrought iron gun barrels by first twisting iron rods and then welding them together using a forging technique. The gun barrel was additionally reinforced with wrought iron rings. Armstrong created a company where they made guns of several sizes. One of the most famous was his 12-pounder rifled gun with a 7.6 cm (3 in) barrel and a screw lock mechanism.

The artillery of the Second World War (WWII), in particular the Soviet Union, probably had the largest potential among European armies. At the same time, the Red Army experienced the purges of Commander-in-Chief Joseph Stalin and endured the difficult Winter War with Finland at the end of the decade. During this period, Soviet design bureaus adhered to a conservative approach to technology.

The first modernization efforts came with the improvement of the 76.2 mm M00/02 field gun in 1930, which included improved ammunition and replacement barrels on parts of the gun fleet, the new version of the gun was called the M02/30. Six years later, the 76.2 mm M1936 field gun appeared, with a carriage from the 107 mm.

Heavy artilleryall armies, and quite rare materials from the time of Hitler’s blitzkrieg, whose army crossed the Polish border smoothly and without delay. The German army was the most modern and best equipped army in the world. The Wehrmacht artillery operated in close cooperation with the infantry and aviation, trying to quickly occupy territory and deprive the Polish army of communication routes. The world shuddered upon learning of a new armed conflict in Europe.

The artillery of the USSR in the positional conduct of combat operations on the Western Front in the last war and the horror in the trenches of the military leaders of some countries created new priorities in the tactics of using artillery. They believed that in the second global conflict of the 20th century, mobile firepower and precision fire would be the decisive factors.

Continuation. For the beginning, see “T and V” No. 1.3/2000

60-MM COMPANY MORTAR GROUP D

Dorovlev sent working drawings of a 60-mm company mortar to the Art Directorate on January 19, 1932. By the way, then it was called not a mortar, but a 60-mm company mortar, but by 1933 in the documentation it was already constantly called a mortar.

Data from the first 60 mm mortar

Caliber, mm 60

Mortar weight, kg 20

Weight of fragmentation mine, kg 1.6

Explosive weight, kg 0.24

Firing range, m 1200

The trunk is smooth. The plate was screwed into the breech, ending in a ball heel. The rectangular base plate measuring 400 x 200 mm was presented in two versions in the project. The machine had lifting and turning mechanisms and a spring shock absorber. To be carried on human packs, the mortar was disassembled into three parts: the barrel (body) weighing about 7 kg, the machine - about 9 kg and the base plate - about 4 kg.

The artillery department approved the working drawings of the mortar and ordered two prototypes from the Red October plant, and each mortar should have two plates (1st and 2nd options). Also in 1932, 60-mm company mortars were tested, but were not accepted for service due to poor accuracy of fire.

But she did not give up the 60-mm mortars of Group D. In 1936, factory No. 7 produced prototypes of the new 60-mm company mortar "60-RM". The weight of the mortar is 22.1 kg, the weight of the mine is 1.6 kg. The weight of the explosive is 0.13 kg. The firing range is 1845 m. For tail cartridges, factory No. 58 developed a special No. 24 caliber sleeve. In the summer and autumn of 1936, the mortar underwent field tests at NIAP. The initial speed of a mine weighing 1.7 kg with an M-1 fuse was when charged: 4 g - 65 m/s, 8 g - 95 m/s, 12 g - 125 m/s and 16 g - 140 m/s. The mortar did not pass the tests due to poor stability, unsatisfactory accuracy and fragility of the shock absorber.

Plant No. 7 redesigned the mortar, and at the same time assigned it its own index - “RM-7”. On May 17, 1937, factory tests of the RM-7 mortar began at NIAP in the presence of the designer of plant No. 7 Shavyrin.

It’s interesting that this mortar’s plate was no longer rectangular, but round. The firing was carried out with mines weighing 1.7 kg and a charge: the main one was 4 g, plus three additional ones of 4.5 g each. The mortar did not withstand the tests. At the end of 1937 - beginning of 1938, new factory tests of the 60-mm company mortar from Plant No. 7 were carried out at NIAP. This mortar received a new factory index - “7-8”.

Mortar data "7-8" (as of September 27, 1937)

Caliber, mm 60

Mine channel path length, mm 728

Charging chamber volume, dm³ 0.345

Barrel weight, kg 5.4

Mortar weight, kg:

in combat position 16.3

in stowed position 18.5

Weight of fragmentation mine, kg 1.7

Weight of explosive in mine, kg 0.13

Full charge weight, g 16.5

Mine initial speed, m/s 135

Firing range, m 1500

Pressure in the channel, kg/cm² 150

However, more than 7 years of efforts with 60-mm company mortars did not bring success, and it was not accepted for service.

82MM BATTALION MORTAR

History of creation

The first 82 mm mortar was designed by Group D on the basis of the captured 81 mm Stokes-Brandt mortar. Working drawings of the 82-mm mortar were sent by N.A. Dorovlev to the Artillery Directorate on November 29, 1931.

Why did Group D mortars have a caliber of 82 mm and not 81.4 mm, like the Stokes-Brandt mortars in the rest of the world? Dorovlev justified the difference in calibers as follows: the mines of battalion mortars of foreign armies could be used by our mortarmen when firing from our mortars, while our mines were not suitable for firing from foreign mortars. In my opinion, such a rationale is nothing more than wit on the stairs. In the 1930s, was it possible to plan in advance the mass surrender of mortar weapons to the enemy? And during the First and Second World Wars, artillery systems without shells were captured more often than shells without artillery systems. Most likely, Dorovlev and Co. were afraid of the mines jamming in the mortar channels, and perhaps this was due to the “tricks” with the centering belts.

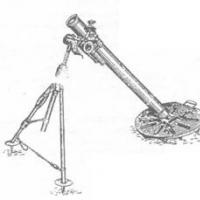

According to the design, the mortar barrel was smooth. A breech with a ball heel is screwed onto the end of the pipe to rest against the plate. A clip is put on the barrel, connecting the barrel to the machine. The cage is equipped with shock-absorbing springs.

The machine is two-wheeled with vertical and horizontal guidance mechanisms. The wheels are hung out in the combat position. On the battlefield, the machine was rolled by hand.

The number of charges is 5, their weight is from 6 to 62 g.

Design data of the 82-mm mortar

Caliber, mm 82

Barrel length, mm/club 1220/15

Vertical guidance angle +40°; +80°

Horizontal guidance angle 6°

Weight of the mortar in firing position, 75 kg.

Barrel weight with clip, kg 22

Weight of the machine with wheels, kg 38

Base plate weight, kg 14

Rate of fire, rds/min 15-18

Ballistic dataHaving examined the working drawings, the artillery department approved them, and on January 7, 1932, gave a pilot order for five 82-mm mortars to the Red October plant.

Field tests of 82-mm mortars manufactured at the Red October plant began on June 17, 1933 at NIAP. The weight of the wheeled mortars was 81 kg. Shooting was carried out with captured mines with six-wing stabilizers. In total, about 10 thousand mines were captured from the Chinese. They fired at distances from 1800 to 80 meters.

The quality of mortars and domestic mines was unsatisfactory, and tests came one after another. Plants No. 13 (Bryansk) and No. 7 (Red Arsenal) joined the work on mortars.

82-mm battalion mortar mod. 1936

82-mm mortar mod. 1937, first release in combat position with MP-82US sight

82-mm mortar mod. 1937, produced 1942 – 1943 in combat position with MPB-82 sight

82-mm mortar mod. 1937, latest release in combat position with MPM-44 sight

82-mm mortar mod. 1943 in combat position with MP-82 sight

82-mm mortar model 1941 in combat position with MPB-82 sight

82-mm mortar model 1937 in a firing position

Base plate arr. 1937

Base plate arr. 1941

The barrel of an 82-mm mortar at the moment of firing

1 – trunk; 2 – mine; 3 – fire transfer holes; 4 – stabilizer tube; 5 – additional charges; b – tail cartridge; 7 – striker; 8 – breech

Additional charges for the 82-mm ten-fin mine (ring charges)

Equipping an 82-mm six-fin mine with additional boat charges

82 mm fragmentation mine

82 mm smoke mine

Gradually, Plant No. 7 became a leading developer and manufacturer of mortars.

In 1935-1936, small-scale production of 82-mm battalion mortars began. By November 1, 1936, the Red Army had 73 82-mm battalion mortars, although according to the states they were supposed to have 2586 pieces.

82-mm mortars received their first baptism of fire in August 1939 with the Japanese on the Khalkhin Gol River. A total of 52 mortars were used on the Soviet side. By the way, the Japanese had about the same number (60 pieces). During the fighting, 46.6 thousand mines were spent.

Mortar device mod. 1937

82-mm mortar mod. 1937 in 1942, it underwent some changes, in particular, the leveling mechanism was located directly on the right leg of the biped. A number of minor changes were made to the mortars produced in 1942 and 1943. Finally, in the mortars produced since 1944, a swinging sight was introduced and there was no mechanism for precise leveling.

Battalion mortar data| Arr. 1937 (issued 1944) | Arr. 1941 | Arr. 1943 | |

| Weight in traveling position (without sight) on wheels, without packs | 58 | 58 | |

| Vertical guidance angle | +45"; +85° | +45°; +85 3 | +45°; +85° |

| Horizontal firing angle without rearranging the biped and the plate, at an elevation angle of +45° | ±3° | ±5° | ±5° |

| rotating mechanism ±10° | rotating mechanism ±10° | ||

| rotating mechanism and fuzzy leveling mechanism | rotating mechanism and rough leveling mechanism | ||

| Horizontal firing angle obtained by rearranging the biped (without rearranging the plate) | up to ±30° | up to +25° | up to ±25° |

| Rate of fire without aiming correction, rds/min | up to 25 | up to 25 | up to 25 |

| Practical rate of fire with aiming correction after each shot, rds/min | up to 15 | up to 15 | UP TO 15 |

82-mm mortar mod. 1941

82-mm battalion mortar mod. 1941 was different from the model. 1937 with the presence of a detachable wheel drive, a base plate of an arched design (like the 107 mm and 120 mm mortars), as well as a bipedal design. The wheels were put on the axle shafts of the biped's legs and removed when firing.

Design improvements were subordinated to the technological capabilities of production and aimed at reducing the weight of the mortar, labor costs in its manufacture and improving maneuverability. Ballistic characteristics of the mortar mod. 1941 were similar to the 1937 model.

82-mm mortar mod. 1941 had some conveniences during transportation compared to the 1937 model, but it was less stable when firing and had worse accuracy compared to the 1937 model. 1937.

In order to eliminate the shortcomings of the 82-mm mortar mod. In 1941, it was modernized. During it, the design of the biped, wheel and sight mount was changed. The modernized mortar was named 82-mm mortar mod. 1943.

That's why mortars mod. 1937 during the Great Patriotic War were produced in parallel with mortars mod. 1941 and arr. 1943.

In 1937, 1587 82-mm mortars were produced, in 1938 - 1188, in 1939 - 1678. In the first and third quarters of 1940, three NKV factories (Nos. 7,106 and 393), as well as the Kirovsky, Gorlovsky and " Red October" was given the task to produce 6,700 82-mm mortars. By August 1, 1940, 5,543 mortars were manufactured at a price of 6,750 rubles. a piece.

Ammunition for 82 mm mortars

For firing from 82-mm mortars of all types, six- and ten-feather fragmentation mines and six-feather smoke mines were used. In addition, propaganda mines were occasionally used.

82-mm fragmentation mines 0-832 and 0-832D produced 400-600 lethal fragments weighing more than 1 g. The radius of a continuous lesion was 6 m, and the radius of an actual lesion was 18 m. The area of a continuous lesion is usually called the area on which, when one ruptures mines hit at least 90% of all standing targets. The area of actual damage is usually called the area on the edges of which, when one mine explodes, at least 50% of all standing targets are affected.

Data min

* – smoke-forming substance weight 0.41 kg

Trays with 82 mm mines

82-mm mortar IS-7

In 1942, the design bureau of plant No. 92 created the 82-mm IS-7 breech-loading mortar with recoil devices. When designing it, components and assemblies of the experimental 76-mm F-23 battalion howitzer were used. The IS-7 had elevation angles from +45° to +85°. The mortar used standard mines from 82 mm mortars. Firing range - about 3000 m. Sight - MP-41.

Several prototypes of the IS-7 mortar were made, but it did not go into mass production.

At the end of 1942, the IS-9 installation was developed - placing an 82-mm IS-7 mortar in a BA-64 armored car. In 1943, this development received the index C-13. The S-13 was not accepted for service.

Carrying an 82-mm mortar mod. 1943 and mines in trays on human packs

Capping box for 10 pieces 82 mm min

Horse pack No. 1 with loaded material part of an 82-mm mortar mod. 1937

Horse mortar pack No. 2 with a loaded box of spare parts and trays with mines

Horse mortar pack No. 3 (No. 4) with loaded ammunition

The 37 mm mortar-shovel is a hybrid of a small sapper shovel and a small-caliber mortar. The handle of the shovel was a mortar barrel 520 mm long, and the blade of the shovel played the role of a base plate and was made of armor steel. An additional support was used as a bipod, attached to the upper part of the mortar barrel. The mortar was equipped with fragmentation mines, which were carried by the shooter in a special bandoleer with shoulder straps. There were no sighting devices, so shooting was carried out by eye. The mortar was used throughout 1939-1942. Captured mortars served in Germany under the designation “3.7-cm Spatengranatwerfer 161(r)”. By the beginning of the war, at least 16 thousand mortars were in service. Mortar performance characteristics: caliber – 37 mm; weight – 2.4 kg; mortar mine weight – 500 g; maximum firing range – 250 m, minimum – 60 m; initial mine speed - 70 m/s; rate of fire – up to 30 rounds per minute; calculation – 1 person.

50-mm company mortars mod. 1938, 1940 and 1941 They are a smooth-bore rigid system with an imaginary triangle diagram. The mortar was constantly improved in terms of weight reduction and firing safety, which was reflected by changes in its designation over the years. The ammunition consisted of a six-feather fragmentation steel mine and a four-feather fragmentation cast iron mine. The mortars captured by the Wehrmacht were used under the designation “5-cm Granatwerfer 205/1/2/3(r)”. A total of 166.3 thousand mortars were fired. Mortar performance characteristics: caliber – 50 mm; weight – 9 – 12 kg, length – 780 mm; barrel length – 553 mm; mine weight - 850 g; initial speed – 95 m/s; rate of fire - 32 rounds per minute; firing range – 100 – 800 m; calculation - 2 people.

Mortar model 1936/37/41/43. was developed on the basis of the Stokes-Brandt mortar and put into service in 1936. Its design was made according to a rigid design (without recoil devices) and consisted of a barrel, a two-legged carriage, a base plate and sighting devices. To fire a shot, the mine was lowered with a stabilizer (tail) into the muzzle of the barrel. The 1937 model mortar differed from its predecessor in having a more rigid round base plate with a side cut. In addition, the design of the two-legged carriage was changed, in particular, the stroke of the shock absorber spring was increased and the sight mount was improved. The 1941 model mortar differed from previous models in its simplified manufacturing technology. The 1943 model mortar was a modernized version of the model. 1941 and featured a modified design of the biped, wheel and trailer mount. Mortars and ammunition were transported on horse-drawn carts or on vehicles available to the troops. In mountain rifle and cavalry units, mortars and ammunition were transported on horse-drawn packs. For short distances on the march (up to 10-15 km), as well as when changing firing positions, mortars and mines were carried by crews on special human packs. For firing from mortars of all types, six- and ten-feather fragmentation mines were used, as well as smoke and propaganda mines. A total of 168.3 thousand mortars were fired. Mortar performance characteristics: caliber – 82 mm; weight in combat position - 56 - 62.7 kg; mine weight - 3.6 kg; initial mine speed - 211 m/s; rate of fire - 25 rounds per minute; The minimum firing range is 100 m, the maximum is 3 km.

The mortar was put into service in 1939, but serial production of mines for it was established only at the beginning of 1941. The mortar barrel consisted of a pipe and a screw-on breech. The shot was fired in two ways: by the action of the firing mechanism of the firing device, which was cocked after loading the mortar; hard self-piercing of the mine when lowering it into the barrel. The biped is connected to the mortar barrel through a spring shock absorber. The base plate was a round stamped all-welded structure. The mortar had an unsprung wheel drive, consisting of a frame, two wheels and a box for spare parts. The mortar was transported in 13 packs. A total of 6.6 thousand mortars were fired. Mortar performance characteristics: caliber – 107 mm; trunk length – 1.7 m; ground clearance – 450 mm; weight in stowed position - 850 kg, in stowed position - 170 kg; projectile weight - 7.9 kg; rate of fire - 6-16 rounds per minute; initial mine speed - 156 - 302 m/s, minimum firing range - 700 m, maximum - 6.3 km; transportation speed on the highway is 40 km/h.

The mortar was developed on the basis of the French “120-mm Mle1935” (Brandt) and was produced since 1939. It had an attached wheel drive for towing by horses or a truck at a speed not exceeding 18 km/h when driving on cobblestones, and at speeds up to 35 km/h when driving on the highway. The shot was fired by piercing the capsule under the weight of the mine, or using a trigger mechanism - for safety purposes when firing powerful charges. The charge was placed in the shank of the mine; to increase the range, there were additional charges in fabric caps, manually attached to the shank. After the start of the war, the 1941 model was mass produced, simplified and without wheels and a front end. In 1943, the 1943 model mortar was adopted for service. The barrel design was simplified, which made it possible to replace a broken firing pin without disassembling the mortar. A fuse was installed on the muzzle to prevent double loading. The mortar's ammunition included: high-explosive fragmentation, high-explosive, incendiary, smoke and illumination mines. During the war, 44.3 thousand mortars were fired. Mortar performance characteristics: caliber – 120 mm; weight – 280 kg; ground clearance - 370 mm; trunk length – 1.8 m; mine weight - 16 kg; initial speed – 272 m/s; firing range – 6 km; rate of fire - 15 rounds per minute; transition time from traveling to combat position - 2 - 3 minutes; transportation speed on the highway is 35 km/h.

The MT-13 mortar was put into service in 1944 and was a smooth-bore rigid system on a rigid (without recoil devices) carriage with a wheeled, sprung ride. The lifting and balancing mechanisms and sighting devices were mounted on the carriage. The problem of transporting the mortar was solved in a new way: it was attached to the tractor with a barrel on which a special pivot foot was attached. Loading was carried out from the breech, for which a swinging barrel was used, which was brought to a horizontal position at the time of loading.

After opening the bolt, a tray was hung on the axle axis of the barrel wedge, onto which the crew laid the mine and manually sent it into the barrel bore. After the mine was sent into the barrel, it returned to the firing position under the influence of its weight. This also automatically eliminated double charging. The main ammunition, a 12-point 160-mm high-explosive mine F-852, weighed 40.8 kg and contained 7.7 kg of explosives. The fundamental difference between the MT-13 mortar round and all other domestic mortars was the short sleeve into which the mine stabilizer was inserted. The sleeve was introduced to seal off the powder gases during firing. During the war, 798 mortars were fired. Mortar performance characteristics: caliber – 160 mm; trunk length – 3 m; weight – 1.2 t; initial speed – 140-245 m/s; mine weight - 41 kg; rate of fire - 10 rounds per minute; firing range: minimum – 630 m, maximum – 5 km; transportation speed on the highway is 50 km/h.

The M224 LWCMS 60mm mortar system is carried by a crew of four. This standard weapon of the Army Infantry and Marine Corps is intended for fire support of small maneuverable units with high-explosive fragmentation, illumination and smoke mines

Mortars are part of field artillery. They are designed for mounted firing at hidden targets, as well as for the destruction of field fortifications, and differ from cannons that fire at targets with direct fire along a low flat trajectory, and howitzers, which usually fire at hidden targets that are not visible from the firing position along a mounted trajectory .

The mortar fires its ammunition (mine) along a high trajectory, which allows it to hit targets behind hills, in narrow streets, in ravines and trenches; the latter fighting quality made it particularly useful in the trench warfare of the First World War. The mortar can be a very simple system: simply throw a shell down the barrel and fire as fast as a soldier can throw rounds down the barrel (20 rounds per minute; it's quite possible to throw every three seconds). Plus, mortar systems can be carried by crews, a light mortar can weigh up to 23 kg, and even ready-to-fire heavy towed mortars weigh 150 kg, which is not in favor of, for example, the 155-mm light howitzer M777 from BAE Systems, which weighs 4200 kg. In addition, the range of light mortars can reach 3.5 km, and the latest heavy systems can reach 10 km.

The mortar appeared as a siege weapon that could be fired over fortress walls to destroy the guns and destroy the structures behind them. Following the reappearance of mortars in World War I, this class of artillery became widespread during World War II, where it played an extremely important, although often underappreciated, role in many combat episodes. For example, Wehrmacht doctrine considered mortars as the main means of fire support for infantry, while “barrel” artillery was reserved for “main attacks.” The mortar began as a small unit's "pocket" artillery - a role that it broadly continues to play today.

Modern mortars fall into three categories: light mortars (typically 60 mm) used at the platoon and company level, medium mortars (81 mm for Western models or 82 mm for Russian and Chinese) used at the company or battalion level, and 120 mm battalion-level mortars, also used in artillery units. The trend is for battalion-level dismounted infantry to be armed with 81mm mortars, while mechanized units are typically armed with vehicle-mounted 120mm mortars. Modern mortars are lighter, fire further, and have greater accuracy and lethality than the systems that were deployed 15 years ago. All this is thanks to the widespread use of new alloys and composite materials in the manufacture of mortar barrels and base plates, automation and digitalization of fire control and progress in fuses and mortar ammunition. These innovations have increased the mortar's capabilities in performing direct fire support missions, despite the changing dynamics of ground combat with its large extent, heterogeneous operations and asymmetry. The obvious conclusion is that under these conditions, the importance of the mortar as a weapon system increases for the combat commander, as well as its contribution to the outcome of the battle.

High mobility is one of the main tactical advantages of the mechanized Stryker units of the US Army. The ability to immediately return indirect fire is critical to maintaining the maneuver advantage of these units.

Light mortars

Which weapons are most suitable as standard weapons for a unit at a particular level are determined by two main factors. First, how does it fit into the combat responsibilities of a unit at this level? In particular, does it correspond to interests and range of tasks? Second, is it compatible with the units' ability to deploy the system, that is, can they move and maintain it? While the advantage of having greater range is obvious, if too many soldiers are needed to carry it or its components, it may not be practical. The difficulty of moving a heavy system and providing sufficient ammunition can negate the value of the increased range. A balance needs to be achieved. Most armies around the world agree that the 60mm mortar is the best choice for a light infantry company. The US Army's FM7-90 mortar combat manual states: "The advantage of the 60mm mortar... lies in its immediate response to the company commander's orders and the speed with which it can go into action."

The US Army and Marine Corps are armed with the M224 LWCMS (Lightweight Company Mortar System) light mortar system with an effective fire range of 70 meters to 3500 meters. A weapon's minimum range is just as important as its maximum, as it determines how close in front of friendly forces it can fire. This can be critical to thwarting an attack that threatens to overwhelm one's own positions, or to deter an enemy attempting to close in on allied positions without returning artillery fire. The M224 mortar and its 20 percent lighter variant, the M224A1, are supplied by General Dynamics Ordnance and Tactical Systems (GDOTS). This family of mortars fires high explosive, smoke (white and red phosphorus), illumination (visible and infrared) and practical mines. In turn, Saab offers its M1061 MAPAM (Multi-Purpose Anti-Personnel Anti-Materiel) mortar ammunition, which can be used with the M224/A1 mortar and fired at a smaller distance from friendly forces thanks to its controlled scattering of fragments; in addition, it is capable of penetrating the most vulnerable spot of an armored vehicle - the roof, and detonating inside it with a delay.

Another light infantry 60-mm mortar under the designation M6 Mortar is produced by the Austrian company Hirtenberger. In addition to the Austrian army, it was adopted by the British army and marines under the designation M6-895 (895 barrel length in mm), the maximum range of which is 3800 meters. In the case of the British, the previous concept, according to which the light mortar was excluded in favor of the hand grenade launcher, was completely changed. However, combat experience during the British invasion of Afghanistan in 2001–2013 allowed us to appreciate the advantages of a light mortar, which forced us to reconsider plans to replace it. A tripod-mounted automatic grenade launcher (AG) is also sometimes considered as a replacement for a light mortar. However, the characteristics of the projectile trajectory of the AG are closer to the mounted fire of a howitzer. In the case of AG, this makes it difficult to fire on reverse slopes. In addition, they do not have such a diverse range of ammunition.

Mortar M6 Mortar of the Austrian company Hirtenberger

One of the features of the 60mm mortar is that, although greater accuracy and range are achieved when mounted on a bipod and using the horizontal and vertical guidance mechanism, it allows visual aiming and hand-held fire and thereby quickly hit targets. Taking this aspect into account, DSG Technology has developed an ultra-light 60mm iMortar mortar for small units. With a mass of 5.5 kg and a length of 900 mm with an integrated aiming system, it is well suited for a small combat group, as evidenced by its short range of 1.2 km.

Ultralight 60-mm mortar iMortar

The American army adopted the 120-mm Elbit Soltam smoothbore mortar, which in the ground version with a bipod was designated M120; this mortar is used at the battalion level

Towed 120mm heavy mortars have been adopted by the US Marine Corps because they can be easily transported by helicopter. The EFSS self-propelled expeditionary fire support system includes a 120 mm TDA rifled mortar and a light Growler tractor

Medium mortars

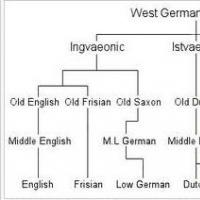

The 81 mm caliber (actually 81.4 mm) is the most common in Western armies, while the 82 mm caliber is typical of Russian and Chinese weapons. Although 82 mm mortars were common in the Soviet army during World War II, they were subsequently replaced by 120 mm mortars in most units. The exception was the transportable, towed and self-propelled smooth-bore mortar 2B9 "Cornflower" of 82 mm caliber on a wheeled chassis, which was put into service in 1970 and used during the Afghan War in 1979–1989. It is also still in service with the Russian Airborne Forces. Unlike traditional mortars, this mortar fires either single shots or in automatic mode using four-round magazines. The range of the mortar, capable of firing high-explosive fragmentation, smoke, illumination and armor-piercing shells, is 4270 meters. The Chinese army is armed with the Type 67, a modernized Soviet regimental mortar PM-41, which was adopted back in 1941. This mortar was widely used in the Vietnam War.

Smooth-bore mortar 2B9 "Vasilek" 82 mm caliber

The United States has used advanced technologies to improve its 81-mm mortars, of which the newest is the M252 model weighing 42.3 kg. It is the standard weapon of the battalion level of the Army light infantry units, and has also been adopted by the Marine Corps. This 81 mm mortar was also installed on a modernized version of the M113 armored personnel carrier, designated M125; The mortar was fired through an open hatch on the roof of the hull. It is also installed on the Marine Corps LAV-M Mortar and transported on the M1129 Styker mortar carrier (main armament is a 120 mm mortar), where it is removed from the vehicle for firing. The M252 has a range of 5,608 meters when firing all types of 81mm ammunition.

The Mo 81 LLR mortar (Leger Long Renforce - light long reinforced) developed by the French company Thales is in service with the French and Irish armies and is offered with a shortened barrel 1.1 meters long (Leger Couf) and with an extended barrel 1.5 meters long (Leger long ). The standard range is 3100 meters, but when firing extended range mines it increases to 5600 meters. The French company Nexter supplies mortar ammunition through its subsidiary Mecar, which produces several types, such as the 155 mm MPM (Metric Precision Munition) with a maximum range of 40 km. Nexter has also developed and prepared for production on the basis of its armored combat vehicle VBCI (Vehicule Blinde de Combat d'Infanterie) a 120-mm mobile mortar system, which has been ordered but not yet purchased by the French army.

Mo 81 LLR mortar manufactured by the French company Thales

All 81mm shells are feathered (with stabilizing planes), and the most common type is high-explosive fragmentation. The adoption of multi-mode fuses for high-explosive fragmentation mines allows the crew to easily select the detonation mode of the projectile immediately before firing. Such fuses, such as the M734, can be installed in several modes: impact, delayed (allows you to break through a roof or shelter) or remote (detonated in the air over a target with scattering of fragments over a large area). For example, the temporary fuse of an illumination mine is installed in such a way that the lighting mixture is ignited in the housing lowered over the target by parachute and burns for 50-60 seconds with a brightness of 525,000 candles. The lighting composition can be equipped either to create illumination in the visible range or in the infrared. Smoke shells are filled with red phosphorus granules, which are ignited to produce a thick smoke screen. Another filler in mortar shells, white phosphorus, instantly creates a smoke screen, reducing visibility in the visible and infrared spectrum. It burns hot and can cause burns, but its instant action makes it ideal for marking targets.

Elbit's SPEAR mortar system has low recoil forces when firing, which allows it to be installed on light tactical vehicles. The system installed on the pickup truck has already been tested by American special forces in Afghanistan

Experience in the combat use of mortar weapons in local conflicts of the late 20th - early 21st centuries.

Mortars, as a class of weapons, became widespread during the Second World War. It was then that this weapon became one of the main artillery fire support weapons for tactical-level infantry units (platoon-company-battalion).

On the eve of World War II, virtually all countries participating in it adopted various mortars. So on August 1, 1940. The Red Army had 5,543 82-mm mortars in Wehrmacht units by June 1941. there were 11,767 mortars (six 81 mm in the machine gun company of each infantry battalion). Light 50, 60 and 81 (82) mm mortars become the standard artillery system of infantry companies and battalions - infantry artillery.

What determines the infantry’s choice of mortars?

Firstly, the mortar has a fairly high accuracy and firing range, ensuring reliable destruction of enemy personnel, weapons and unarmored equipment in battle. Secondly, it provides the opportunity for relatively hidden firing (a closed firing position and low sound intensity when fired make it difficult for the enemy to detect the crew).

Crew of the 82-mm mortar mod. 1938 During the Great Patriotic War

Thirdly, the high rate of fire - from ten to twenty rounds per minute ensures a high density of fire in critical moments of the battle. Fourthly, the relatively light weight of weapons and ammunition increases the maneuverability of infantry units and reduces their dependence on supporting artillery fire, which is not always effective due to the time required for passing commands and the possibility of hitting friendly troops when the safe distance radius (RDR) decreases.

The average weight of an 81/82 mm mortar, disassembled into three main parts (barrel, bipod and base plate) is about 50 kg. The weight of an 81/82 mm high-explosive fragmentation mine ranges from 3.2 to 4.4 kg. The classification of 81/82 mm mortars by caliber deserves special attention. In fact, these weapons are of the same caliber, as will be discussed below.

The first episodes of combat use of mortars

The first episodes of combat use of mortars were noted during the defense of Port Arthur in 1904. (mortar designed by Lieutenant General of the Artillery of the Russian Army Leonid Nikolaevich Gobyato). During the Second World War, mortars were in service with the armies of all warring parties. The first Soviet 82-mm mortar was adopted by the Red Army under the name BM-36 in 1936. In SKB-4 Boris Ivanovich Shavyrin (Leningrad) an 82-mm battalion mortar mod., which is easier to manufacture and operate, is being created. 1937 (BM-37), replacing its predecessor. Battalion mortars (this concept refers to all portable 81 and 82 mm systems) during the battle were directly subordinate to the commanders of infantry companies and battalions.

This made it possible to quickly and with high accuracy hit enemy infantry and machine gun crews directly in front of the battle formations of friendly troops, which is very problematic when using cannon artillery (cannons and howitzers).

The first baptism of fire of the BM-37 took place in the area of the Khalkhin Gol River in battles with the Japanese invaders, providing the infantry with indispensable assistance in destroying the enemy in the trenches and on the reverse slopes of the hills.

In 1941 and 1943 The Soviet battalion mortar was modernized. During the Great Patriotic War, battalion 82-mm mortars mod. 1937, 1941 and 1943 were in service with rifle battalions, serving as the main means of fire support for rifle companies. 82-mm battalion mortar mod. 1943 was produced for a long time in the post-war period and is still in service with the Russian army and the armies of other states.

The domestic 82-mm mortar is supported by the fact that during the Great Patriotic War, Soviet crews often used captured German 81-mm and Lendlease American 81-mm mines for firing. A unique example of the development of a domestic modern battalion mortar was shown to the world by the war in Afghanistan of 1979-1989. In the early 1970s. the main 82-mm mortar of the Soviet army BM-43 model 1937/1943. was withdrawn from service with the Ground Forces. Leadership of the USSR Armed Forces until the end of the 1970s. there was no place for 82-mm mortars in a “nuclear missile war.” They remained in service only with the Airborne Forces, and in units of the Ground Forces it was completely replaced by the 120-mm mortar, which was used to arm mortar batteries of motorized rifle battalions. However, the design bureau of the Gorky Machine-Building Plant was proactively developing a new 82-mm mortar.

And not in vain... With the beginning of the war in Afghanistan, it became clear that only portable systems can provide infantry units operating autonomously at a considerable distance from towed and self-propelled artillery with effective direct fire support. Just at this time, factory tests of the 82-mm 2B14 mortar developed in Gorky (Nizhny Novgorod) were carried out. An order was received from the military for the urgent production of a batch of 100 pieces, which passed field and military tests in Afghanistan.

In 1983 The 82-mm mortar 2B14 “Tray” was adopted by the Soviet army. Later, its modification was created - 2B14-1, which had minor design changes. In Afghanistan, 82-mm mortars BM-43 and 2B14 "Tray" were in service with mortar companies of motorized rifle, parachute and air assault battalions of the Limited contingent of Soviet troops.

Since the beginning of the 80s. and Afghan rebels used 82mm mortars. Their main Type 53 mortar was essentially a Chinese version of the Soviet BM-43 mortar. In addition, the Afghan rebels used two identical 60-mm Type 63 and MB mortars made in China and Pakistan, respectively, as well as an 82-mm Yugoslav M69 mortar coming to Afghanistan from Arab countries. In addition to 60 and 82 mm systems, Afghan rebels since 1987. began to receive Spanish 120-mm Esia mortars through the United States.

The 60mm company mortar deserves special attention. The division of mortars into company (up to 60 mm), battalion (75 and 81/82 mm) and regimental (106.7 and 120 mm) came into practice on the eve of World War II. 60-mm systems and domestic 50-mm mortars mod. 1941 infantry companies were armed. However, the domestic 50-mm mortar was discontinued at the initial stage of the Great Patriotic War. Nevertheless, company 60-mm mortars are in service with many modern armies of the world. Already in their very name it is indicated that these weapons belong to the company level fire support weapon complex, i.e. weapons for direct fire support of platoons of infantry companies.

In modern combat operations, especially during local wars and armed conflicts, there is a steady tendency to fragment units and formations into smaller tactical units. In such conditions, small infantry units need their own effective means of defeating the enemy.

The systems of assault weapons (rocket-propelled anti-tank and assault grenades, rocket-propelled anti-tank grenade launchers and flamethrowers) and fire support weapons (large-caliber machine guns and sniper rifles, under-barrel and automatic grenade launchers, man-portable anti-tank missile systems and recoilless rifles) created in recent decades cannot be replaced on the battlefield small caliber mortar. It is indispensable in close combat when destroying the enemy in trenches and folds of terrain, behind reverse slopes, houses and fences. These are precisely the tasks facing company mortars in modern combat. At the same time, the presence of mortar men directly in the combat formations of infantry units simplifies fire control for commanders and facilitates a rapid response to a rapidly changing combat situation.

Carrying mortar shells by Soviet infantrymen in Afghanistan. 80s

The absence of small-caliber mortars in service with the Russian Army is justified by the presence in the weapons system of infantry units at the platoon-company level of 40-mm under-barrel and 30-mm automatic grenade launchers. However, the power coefficient of a 60-mm fragmentation mine is several times higher than that of a similar indicator

30 and 40 mm fragmentation grenades, which significantly affects the reliability of destruction of enemy infantry and fire weapons in field-type shelters, destruction of enemy equipment and fire weapons. A company mortar covers the firing range of an underbarrel grenade launcher by 3-5 times, and with the same firing range as an automatic grenade launcher, it is several times superior to it in terms of weight and dimensions. For example, the weight of a 30-mm AGS-17 automatic grenade launcher with a sight is 30.5 kg, and a 60-mm mortar is three times less.

The "Tray" crew fires at the rebel positions. Afghanistan, 80s

Here is an example of the use of 60-mm mortar fire by a company tactical group of the parachute battalion of the Jordanian Armed Forces at one of the tactical exercises in 2003, which I was able to attend. The paratroopers were faced with the task of destroying the “terrorists” who had taken refuge in one of the nomads.

Supported by the fire of 20-mm cannons from fire support helicopters AN-1 Cobra (USA) and BMP Ratel (South Africa), Jordanian paratroopers dismounted from armored vehicles and blocked the “terrorists.” When the fire from the helicopter and combat vehicles began to pose a danger to the paratroopers approaching the target, fire was opened on the “terrorists” from a 60-mm Type 63 mortar, the firing position of which was located in the combat formations of a dismounted unit.

Under cover of mortar fire

Under the cover of mortar fire (combat rate of fire 10-12 rounds per minute), a pair of flamethrowers crawled towards the object and destroyed the “terrorists” with a salvo from LPO-50 light infantry flamethrowers (USSR). By the way, for some reason the LPO-50 is ignored by domestic anti-terrorist units, although it is much more convenient to burn terrorism out with fire than to “soak it in the toilet.”

There is no information about successful examples of rebels using 60-mm mortars in Afghanistan; these weapons were extremely rare among the Mujahideen. Much more problematic for the Soviet and Afghan troops was the fire of the most common artillery system among the rebels - 82-mm mortars. Former farmers, artisans and students learned to master mortar weapons in training centers and camps in Pakistan and Iran. By the way, this art was taught to them at one time by the same Jordanian non-commissioned officer who masterfully placed 60-mm mines 20-30m ahead of the flamethrowers during an anti-terrorist exercise, covering their advance to the firing line.

By luck, I did not have to deal with his students in Afghanistan... But our garrison, two weeks after my departure from it, was less fortunate in this regard. November 27, 1987 The garrison of Soviet and Afghan troops in the city of Asadabad was subjected to a massive fire attack using all artillery weapon systems available to the Mujahideen. It all started with the defeat of a Mi-8 helicopter in the air by fire from a Stinger MANPADS. Then the rebels opened fire on the garrison and residential areas of the city with 107-mm rockets and, under their cover, dragged 82- and 120-mm mortars to the firing lines. It was in Asadabad that the delivery of the 120-mm Esia mortar to the Afghan rebels was confirmed. Military personnel of the Asadabad garrison learned about the enemy's use of 120-mm mortars by the characteristic aluminum tail of exploding mines.

Like the Stinger, the Esia 120mm mortar was of American origin, although it was produced in Spain. The fact is that at this time the United States decided to adopt a 120-mm mortar system into service with the Marine Corps in order to ensure the supply of expeditionary forces with NATO-standard 120-mm mortar ammunition (at that time the US had only 60-, 81- and 106.7 mm mortars). Their choice fell on the Spanish mortar. It was necessary to test it in Afghanistan in order to make a final decision on its adoption. Our intelligence learned in advance that a new powerful weapon system was being adopted by the Afghan rebels, and the first confirmation of this was given by the scouts of the 334 ooSpN (a separate special forces detachment), when the reconnaissance group of Lieutenant Igor Matveychuk was killed in an ambush in Surubi County in October 1987 field commander of the Mujahideen, seizing from him firing tables from the 120-mm Esiya mortar and other documentation.

120-mm mortars were also used by Soviet troops in Afghanistan, but battalion 82-mm “Tray” mortars earned great popularity among our troops. The Soviet infantry, leaving for the mountains, did not part with them. The “tray” was much lighter than the Chinese 82-mm mortar in service with the Mujahideen, but maneuvering the weapon in battle was not particularly required. Unlike the Soviet troops, they used defensive tactics.

The rebels set up stationary mortar positions in the highlands in strongholds of fortified areas or in “greenery” (irrigated valleys and gorges) near their bases. In the highlands and in winter, they often froze the mortar base plate into the ground. With this method of equipping a firing position, it was possible to conduct intense concentrated fire in series of several mines without restoring aiming. It is this method of shooting, after preliminary zeroing and waiting for a convenient moment to open fire, that provides the maximum effect of defeating openly located manpower that does not have time to hide from the fire. Major Solovyov’s subordinates from the air assault battalion of the 66th Motorized Rifle Brigade came under such mortar fire on December 2, 1986 during the capture of the Ogz and Shpolkai fortified areas in the south of Nangarhar province. Only the next day did the paratroopers manage to knock the enemy off the ridge and capture an 82-mm mortar with a base plate frozen into the ground, then the reason for the high accuracy of fire from the enemy crew became clear.

In the foreground are captured 60- and 82-mm mortars captured by our troops in Afghanistan. On the left is S. Bekov, Advisor to the CPSU Central Committee in the Vostok operational zone.

In addition to standard 82-mm battalion mortars, our troops also used captured mortars in Afghanistan. First of all, 60-mm systems, but such cases were sporadic and not widespread due to the small number of these weapons and mines for them in the Mujahideen’s weapons system. So the scouts of the 3rd company of the 154th special forces during the winter of 1985-1986. used a Type 63 60mm mortar captured from the enemy until they ran out of mines.

The experience gained in handling non-standard weapons was useful to the scouts in battle on March 29, 1986. on the Afghan-Pakistan border in the Krer gorge (transshipment base for the Shahid Abdul Latif and Fatah caravans). At a critical moment in the battle, the scouts deployed an 82-mm mortar they had captured in battle. Type 53 towards the enemy. Thanks to the fire, they managed to stop the counterattack of the superior rebel forces and ensure the evacuation of the wounded. Scouts of the 22nd Special Operations Brigade used captured 82-mm mortars, installing them in the bodies of combat vehicles (captured pickup trucks and standard Urals),

Armed forces of the USSR in the 80s. We didn’t focus on the “Afghan war.”

In 1984 The 2I27 product, which is a UAZ-469 vehicle with a kit for installing, stowing and transporting two 82-mm mortars and transportable ammunition, is being supplied to the Ground Forces for separate air assault brigades (ADB) and battalions (ODShB). In the UAZ-469 vehicle, in addition to two 2B14-1 mortars and spare parts for them, there were: in the first version - 116 mines (36 in 12 trays and 80 in 8 park boxes), a crew with a driver - 2 people; in the second option - 76 mines of transportable ammunition (36 in 12 trays and 40 in park boxes), crew with a driver - 4 people. However, this weapon was not suitable for the conditions of Afghanistan; it was suitable for raid operations during a large-scale war.

Mortars were actively used in the 90s. last century during the Yugoslav War

In Afghanistan, another method, or rather technique, of using mortars on a vehicle chassis was developed - the use of nomadic mortars. The rebels used this trick. The Afghan mujahideen, using roaming fires (ROF) tactics, transported their 82mm mortars in the back of pickup trucks and sometimes on pack animals or tractor trailers. At the same time, they created in advance the necessary supply of mines near the intended firing position and, at the appointed time, delivered only a mortar to it.

Moreover, the creation of caches of ammunition near firing positions concerned not only mortars, but also other weapon systems. This is what explained the high mobility of gangs, unencumbered by carrying ammunition. Even machine gunners had their hiding places in the area of responsibility or in places where ambushes and other armed actions were carried out.

Whoever knew this was no longer surprised that when inspecting killed or captured rebels, they had only a minimum supply of ammunition from 30 to 180 for a machine gun and carbine (rifle) and a little more for machine gunners, and grenade launchers rarely carried more than 2- 3 grenades. Special forces reconnaissance officers always took advantage of this circumstance, catching the enemy by surprise during an ambush or raid.

Crew of the "Tray" mortar of the GRU Special Forces unit. Chechnya, 2005

The Afghan experience in using CBS was also in demand by the domestic army special forces, but in another war. It is reconnaissance and sabotage groups armed with a mortar that are best suited to the tactics of nomadic fire weapons. Mortar fire behind enemy lines, like no other (with the exception of sniper fire), affects the morale of the personnel of the opposing side.

So in Tajikistan in the early 90s. The special forces reconnaissance group successfully applied the KOS tactics using the Yugoslav 81-mm mortar M69 (M081LC), captured from the Mujahideen by reconnaissance officers of the 15th separate special forces brigade back in 1987. The design of this mortar made it possible to mount a domestic mortar sight on it. The Yugoslav mortar was 11 kg lighter than the domestic 82-mm BM-43 mortar, and the firing table on a metal nameplate was attached directly to the barrel. The mortar was transported in a UAZ-469 vehicle, and deployed at the firing position by a crew of three people, not counting volunteer assistants from the Popular Front of Tajikistan.

The tactics of nomadic fire weapons determine several stages of action: collecting intelligence information about the target of the raid; terrain reconnaissance and selection of firing positions; reaching combat positions (firing position, observer-spotter, cover (support) subgroup); fire engagement (target shelling); changing firing position or retreat.

The transportable ammunition of the 81-mm nomadic mortar consisted of ten to forty 82-mm mortars of domestic production. This universal “omnivorousness” of 81- and 82-mm battalion mortars is explained by different approaches to caliber determination. In domestic practice, the caliber of the barrel is designated, and in the West - mines. The versatility of the 81 and 82mm calibers of the mortar allows the use of both mines. For example, the Mujahideen in Afghanistan successfully used Pakistani, British and American 81-mm mines with 82-mm Chinese mortars.

In fact, the difference in caliber of the 81/82 mm mine and the 81/82 mm mortar is the same and amounts to 0.7 mm. It is the absence of contact between the mine and the walls of the barrel when fired, thanks to the annular grooves on the body of the mine that create an “air cushion,” that explains the high accuracy of the mortar’s fire. To ensure high shooting accuracy, the first priority, in addition to correct aiming of the weapon at the target, is the mass of the mine and the same temperature of the propellant charge (main and additional). It is quite difficult to produce mortar shells that are accurate in weight due to the technological features of their production (casting and turning).

Domestic manufacturers mark mines of different weights with a cross-shaped core. Mines with one, two or three “crosses” are classified into three different weight groups. This should be taken into account when firing a series of mines and, especially, when hitting the enemy near friendly troops. Oddly enough, many mortarmen of the Russian army do not know about this, which is confirmed by their actions during the counter-terrorist operation in the North Caucasus. Apparently, the old Soviet artillery school and the experience of the Great Patriotic War, in which Soviet artillery, including mortars, were recognized as the best, have been forgotten.

The mortar crew of the GRU Special Forces reconnaissance unit prepares its mortar for firing. Chechnya, 2005

During the counter-terrorism operation in the North Caucasus, 82-mm 2B14 and BM-43 mortars were widely used by both federal forces and gangs. The federal troops suffered especially significant losses from enemy mortar fire during the capture of Grozny in January 1995. Having an extensive network of informants and observer-spotters, illegal armed groups used the tactics of fire raids to concentrate Russian troops in courtyards and on the streets. In the “Second Chechen Campaign,” the militants, fortunately, “underestimated” mortars, but the federal forces used them quite widely.

Thus, during the destruction of R. Gelayev’s bandit group in December 2003, thanks to the high professionalism of the mortar crew of the army special forces, the federal forces managed to completely block the enemy with fire. For two days, the crew of the 82-mm mortar 2B14 “Tray” held the surrounded enemy in a gorge on the northern slope of the Kusa ridge with harassing fire, and subsequently provided the assault groups with direct fire support. At the same time, the mortar men were in a closed firing position 1.7 km from the assault groups, and the mines were placed 30-50 m from the attackers.

The 82 mm mortar appeared in the early 2000s. It is no coincidence that it is in service with the domestic army special forces. This was influenced by the combat experience of using mortars in Afghanistan and Tajikistan, the foreign experience of the Special Operations Forces, a number of publications in the domestic media and the enthusiasm of individual special forces officers.

Foreign experience Experience in combat use of mortars

Foreign experience Experience in the combat use of mortars by US and British special forces indicates that this type of weapon plays an important role during special operations.

A typical example was the operation of the 22nd SAS Regiment (Special Airborne Services) of the British Armed Forces to destroy Argentine Air Force aircraft on Pebble Island during the Falklands conflict, which took place on May 14-15. The day before, May 10, 1982, two patrols of four people each were landed on the island of West Falklands from helicopters with the task of conducting reconnaissance of the aircraft's base.

Having crossed the strait in collapsible canoes, the patrols equipped two observation posts (OP) and established the presence of 11 Pukara attack aircraft at the reconnaissance airfield. On the morning of May 14, at the opposite end of Pebble Island, three Sea King helicopters landed a detachment of the 22nd SAS Regiment, armed with small arms, grenade launchers and two 81-mm mortars. Arriving at the airfield, a detachment of 40 people divided into two groups and took up their starting positions.

One group of 20 people was supposed to destroy aircraft parked with mortar fire, and the other was to cover their actions and cut off reinforcements from the nearest Argentine garrison. The operation took place in the dark using flare mines and shells from the guns of the destroyer Glamorgan. During the special operation, all Argentine aircraft were destroyed. British losses were two wounded.

It is difficult to find a more effective weapon than the mortar of a reconnaissance and sabotage group when destroying enemy aircraft and helicopters at airfields and landing sites. A wealth of experience in this type of combat against enemy aircraft has been accumulated by various rebel groups in Africa, Latin America, Southeast Asia and Afghanistan. The protection of airfields with an extensive network of outposts and outposts, minefields and engineering obstacles is often powerless from mortar fire.

Armed with portable 60- or 82-mm mortars, small reconnaissance and sabotage groups, operating behind enemy lines at a considerable distance from the main forces, can always count on effective fire support from their own mortar. Even in Afghanistan, where there was an effective system of air support for special forces, in the presence of relatively primitive air defense of the rebels, special forces could not always rely on the help of army and attack aircraft.

In addition to air defense, the work of aviation is also limited by weather conditions. Artillery support is devoid of such shortcomings, but its capabilities are limited by the firing range of cannon and rocket artillery of the Ground Forces. In such a situation, the issue of increasing the firepower of special forces is solved very simply - with our own mortars.

The main advantages of the 82-mm mortar as a special forces weapon are not only its high shooting accuracy, but also the possibility of covert firing, as well as the high mobility of this artillery weapon system.

In the early 2000s. Domestic designers, by order of the GRU General Staff, developed the 82-mm silent mortar system BShMK 2B25. However, due to the short-sightedness of certain officials of the military department, the work was curtailed, and there are no plans to adopt a silent mortar into service with the Russian Armed Forces in the near future. But in vain. The mortar, which has no analogues in the world, has a mass of about 12 kg and a firing range

about 1200m. Moreover, its fragmentation effect mine is several times more effective than a conventional 82-mm high-explosive fragmentation mine, and the sound of a shot is no louder than a hammer hitting wood...

Alas, what kind of silent mortars can we talk about for the domestic special forces if its very numbers are being reduced, while the United States and our other “sworn friends” attach paramount importance to the development of special operations forces.

The high mobility of 60- and 82-mm mortars is ensured by the ability to carry them by personnel, parachute landing (in cargo containers), delivery by helicopter, light vehicles and armored personnel carriers. The kit of the domestic 82-mm mortar 2B14 includes packing devices that allow it to be carried by three servicemen (barrel - pipe, base plate, bipod and sight). The fourth number of the crew carries the mines themselves, but if necessary, they can be carried over short distances by the remaining numbers. When a mortar crew operates in infantry combat formations or as part of a reconnaissance and sabotage group, other military personnel are recruited to carry mines.

In China, where infantry is one of the world's most numerous military branches, universal pack devices are used to carry 82mm mortars and recoilless rifles, heavy machine guns and other fire support weapons. Our servicemen had the opportunity to familiarize themselves with them in Afghanistan. The versatility of the packs is achieved by the presence of a standard back pad with mounting brackets, straps and shoulder straps with shoulder pads. With the help of such a pack, you can carry any types of heavy weapons in standard cases or by securing them to the packs with belts, as well as other loads.

It is clear that the battalion mortar has not lost its importance in modern high-tech warfare. The portable 82-mm mortar in the Russian Armed Forces cannot be replaced by an automatic mortar of the same caliber 2B9 "Vasilyok" or mortars of a larger caliber. Other infantry support weapons of the 21st century, including high-precision ones, are also unable to fully replace them.

Alexander MUSIENKO, reserve colonel

Experience in the combat use of mortars Flight range of mines from a mortar 80 mm

Experience in the combat use of mortars Flight range of mines from a mortar 80 mm Konstantin Mikhailovich Simonov, alive and dead Before the evening drive, another meeting took place

Konstantin Mikhailovich Simonov, alive and dead Before the evening drive, another meeting took place US Eighth Air Force Museum 8th Air Force

US Eighth Air Force Museum 8th Air Force Differentiation of functions

Differentiation of functions Classification of modern Germanic languages Main features of the Germanic group of languages

Classification of modern Germanic languages Main features of the Germanic group of languages Which scientist introduced the concept of valency?

Which scientist introduced the concept of valency? How does a comet grow a tail?

How does a comet grow a tail?