Acetylene structural. Acetylene is the gas with the highest flame temperature! What to do if there is a fire

Acetylene is a gas with a faint garlic odor that condenses into liquid at a temperature of -84°C and a pressure of 62 atm.

Mixtures of acetylene with air are explosive. Liquid acetylene explodes when dust gets into it.

Acetylene is stored and transported either in an adsorbed state on activated carbon or in solutions of carbonyl compounds. 1 volume of acetone absorbs 25 volumes of acetylene (under normal conditions). Acetylene is transported in cylinders filled with activated carbon. Acetylene easily decomposes into carbon and hydrogen when heated.

Chemical properties

Addition reactions

Hydrogen addition

Hydrogen on hydrogenation catalysts reduces alkynes to alkanes.

To stop the reaction at the stage of formation of alkenes, special additives are used for noble group catalysts:

Hydrides are used as chemical reducing agents.

Unlike catalytic hydrogenation, which leads to the formation cis-alkenes, chemical reducing agents give trance-alkenes.

Currently, liquid aluminum hydrides are used in industry:

(RO) 2 AlH – light yellow liquid,

Addition of hydrogen halides

The method is widely used in industry for the production of vinyl chloride, dichloroethane, tetrachlorethylene and other chlorinated derivatives.

The reaction proceeds according to the electrophilic mechanism:

Addition of halogens

The reaction is used to synthesize tetrachlorethylene. In industry, all kinds of products are obtained using wet Ca oxide or hydroxide, soft elimination agents H-X (dehydrohalogenating reagents).

To obtain tetrachlorethylene, a two-stage method is used:

The addition of chlorine to acetylenes occurs very rapidly; safe chlorination can be carried out in a solution of a chlorine carrier:

-complex of antimony pentachloride with pentachloroethane.

Nucleophilic addition reactions to acetylenes

Water connection

Water is a neutral nucleophile.

Reaction mechanism:

Activation of acetylene by a complex with mercury

Addition of alcohols

Alcohols are somewhat stronger neutral nucleophiles than water:

.

.

The reaction of addition of alcohols to acitelenes is called vinylation of alcohols:

Vinyl ethers are a stable form of existence of vinyl alcohols ( enols).

Some properties of vinyl esters

Vinyl ethers are more reactive in electrophilic addition reactions than ethylenes.

The alkoxy group, due to conjugation, causes a significant increase in the electron density on the double bond, which facilitates the ease of formation of a -complex with electrophilic reagents.

For example, the reaction with bromine proceeds with a quantitative yield:

In the presence of acids, vinyl esters can polymerize via a cationic mechanism:

PVBE, so-called Shostakovsky balm, has antiseptic properties, is a substitute for penicillins.

Addition of carboxylic acids to acetylenes

PVA is used as varnishes and adhesives; The hydrolysis of polyvinyl acetate produces polyvinyl alcohol:

Polyvinyl alcohol is indispensable for the preparation of varnishes and enamels.

Addition of hydrocyanic acid

Carbonylation reaction

All acrylic acid derivatives are widely used as polymer materials with individual properties. For example, polyacrylamide is used as a synthetic adhesive, and methyl methacrylate is used as organic glass.

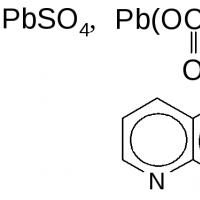

Acetylene nitration

It is carried out with a mixture of sulfuric and nitric acids to obtain tetranitromethane.

Under the reaction conditions, dinitroacetic aldehyde is oxidized, decarboxylated and donitrated:

Acetylene polymerization reactions

Linear polymerization

May occur as dimerization or trimerization:

Vinylacetylene is used in industry to produce chloroprene.

In the presence of copper acetylide, acetylene forms the substance kupren:

High temperature cyclization of acetylene

If you use iron carbonyl as a catalyst, you can even get cyclooctatetraene.

The structural features of acetylene affect its properties, production and use. The symbol for the composition of a substance is C 2 H 2 - this is its simplest and gross formula. Acetylene is formed by two carbon atoms, between which a triple bond occurs. Its presence is reflected in different types of formulas and models of the ethin molecule, which make it possible to understand the problem of the influence of the structure on the properties of the substance.

Alkynes. General formula. Acetylene

Alkyne hydrocarbons, or acetylene hydrocarbons, are acyclic and unsaturated. The chain of carbon atoms is not closed; it contains simple and multiple bonds. The composition of alkynes is reflected by the summary formula C n H 2n - 2. Molecules of substances of this class contain one or more triple bonds. Acetylene compounds are unsaturated. This means that only one valence of carbon is realized by hydrogen. The remaining three bonds are used when interacting with other carbon atoms.

The first and most famous representative of alkynes is acetylene, or ethylene. The trivial comes from the Latin word "acetum" - "vinegar" and the Greek - "hyle" - "wood". The ancestor of the homologous series was discovered in 1836 and later the substance was synthesized from coal and hydrogen by E. Davy and M. Berthelot (1862). At normal temperature and normal atmospheric pressure, acetylene is in a gaseous state. It is a colorless, odorless gas, slightly soluble in water. Ethyne dissolves more easily in ethanol and acetone.

Molecular formula of acetylene

Ethine is the simplest member of its homologous series; its composition and structure are reflected by the formulas:

- C 2 H 2 is a molecular representation of the composition of ethyne, which gives the idea that the substance is formed by two carbon atoms and the same number of hydrogen atoms. Using this formula you can calculate the molecular and compounds. Mr (C 2 H 2) = 26 a. e.m., M (C 2 H 2) = 26.04 g/mol.

- H:S:::S:H is the electron dot formula of acetylene. Such images, called “Lewis structures,” reflect the electronic structure of the molecule. When writing, you must follow the rules: the hydrogen atom, when forming a chemical bond, tends to have the configuration of the helium valence shell, other elements - an octet of outer electrons. Each colon represents a shared or lone pair of electrons in the outer energy level.

- H—C≡C—H is the structural formula of acetylene, reflecting the order and multiplicity of bonds between atoms. One dash replaces one pair of electrons.

Acetylene molecule models

Formulas showing the distribution of electrons served as the foundation for the creation of atomic orbital models and spatial formulas of molecules (stereochemical). At the end of the 18th century, ball-and-stick models became widespread - for example, balls of different colors and sizes, indicating carbon and hydrogen, which form acetylene. The structural formula of a molecule is presented in the form of rods, symbolizing chemical bonds and their number in each atom.

The ball-and-stick model of acetylene reproduces bond angles equal to 180°, but the internuclear distances in the molecule are reflected approximately. The voids between the balls do not create the idea of filling the space of atoms with electron density. The shortcoming is eliminated in Dreiding's models, which designate the nuclei of atoms not as balls, but as points of attachment of rods to each other. Modern three-dimensional models provide a clearer picture of atomic and molecular orbitals.

Hybrid atomic orbitals of acetylene

Carbon in an excited state contains three p orbitals and one s orbital with unpaired electrons. During the formation of methane (CH 4), they take part in the creation of equivalent bonds with hydrogen atoms. A famous American researcher developed the doctrine of the hybrid state of atomic orbitals (AO). The explanation of the behavior of carbon in chemical reactions lies in the alignment of AO in shape and energy, the formation of new clouds. Hybrid orbitals give stronger bonds and the formula becomes more stable.

The carbon atoms in the acetylene molecule, unlike methane, undergo sp-hybridization. The shape and energy of the s- and p electrons are mixed. Two sp orbitals appear, lying at an angle of 180°, directed on opposite sides of the nucleus.

Triple bond

In acetylene, hybrid electron clouds of carbon participate in the creation of σ bonds with the same neighboring atoms and with hydrogen in C–H pairs. There remain two non-hybrid p-orbitals perpendicular to each other. In the ethin molecule they participate in the formation of two π bonds. Together with σ, a triple bond appears, which is reflected in the structural formula. Acetylene differs from ethane and ethylene in the distance between the atoms. A triple bond is shorter than a double bond, but has a greater amount of energy and is stronger. The maximum density of σ- and π-bonds is located in perpendicular regions, which leads to the formation of a cylindrical electron cloud.

Features of chemical bonds in acetylene

The ethin molecule has a linear shape, which is successfully reflected by the chemical formula of acetylene - H—C≡C—H. The carbon and hydrogen atoms are located along the same straight line, and 3 σ- and 2 π-bonds arise between them. Free movement, rotation along the C-C axis is impossible, this is prevented by the presence of multiple bonds. Other features of the triple bond:

- the number of pairs of electrons connecting two carbon atoms is 3;

- length - 0.120 nm;

- rupture energy - 836 kJ/mol.

For comparison: in ethane and ethylene molecules, the length of single and double chemical bonds is 1.54 and 1.34 nm, respectively, the energy of C-C cleavage is 348 kJ/mol, C=C is 614 kJ/mol.

Acetylene homologues

Acetylene is the simplest representative of alkynes, the molecules of which also contain a triple bond. Propyne CH 3 C≡CH is a homologue of acetylene. The formula of the third representative of alkynes, butine-1, is CH 3 CH 2 C≡CH. Acetylene is a common name for ethylene. alkynes obey IUPAC rules:

- in linear molecules, the name of the main chain is indicated, which originates from the Greek numeral, to which the suffix -ine and the number of the atom at the triple bond are added, for example, ethyne, propyne, butine-1;

- numbering of the main chain of atoms begins from the end of the molecule closest to the triple bond;

- for branched hydrocarbons, the name of the side branch comes first, followed by the name of the main chain of atoms with the suffix -in.

- the final part of the name is a number indicating the location of the triple bond in the molecule, for example, butine-2.

Isomerism of alkynes. Dependence of properties on structure

Ethyne and propyne do not have triple bond position isomers; they appear starting with butine. Pentine and the following homologues have carbon skeleton isomers. With respect to the triple bond, spatial isomerism of acetylene hydrocarbons does not appear.

The first 4 homologues of ethin are gases that are poorly soluble in water. Acetylene hydrocarbons C 5 - C 15 are liquids. The solids are homologs of ethine, starting with the C17 hydrocarbon. The chemical nature of alkynes is significantly influenced by the triple bond. type more actively than ethylene, they attach various particles. This property is the basis for the widespread use of ethylene in industry and technology. When acetylene burns, a large amount of heat is released, which is used in gas cutting and metal welding.

Acetylene

The name of this substance is associated with the word “vinegar”. Today it is the only gas widely used in industry, the combustion and explosion of which is possible in the absence of oxygen or other oxidizing agents. Burning in acid, it gives a very hot flame - up to 3100°C.

How acetylene was synthesized

First received acetylene

in 1836 Edmund Davy, cousin of the famous Humphry Davy. He acted water on potassium carbide: K 2 C 2 + 2H 2 O=C 2 H 2 + 2KOH and obtained a new gas, which he called hydrogen bicarbonate. This gas was mainly of interest to chemists from the point of view of the theory of the structure of organic compounds. One of the creators of the so-called radical theory, Justus Liebig, named the group of atoms (i.e. radical) C 2 H 3 acetyl.

In Latin, acetum means vinegar; a molecule of acetic acid (C 2 H 3 O + O + H, as its formula was written then) was considered as an acetyl derivative. When the French chemist Marcelin Berthelot in 1855 managed to obtain “hydrogen bicarbonate” by several methods at once, he called it acetylene

. Berthelot considered acetylene to be a derivative of acetyl, from which one hydrogen atom was removed: C 2 H 3 - H = C 2 H 2. First, Berthelot obtained acetylene by passing vapors of ethylene, methyl and ethyl alcohol through a red-hot tube. In 1862 he succeeded in synthesizing acetylene from the elements by passing hydrogen through a voltaic arc flame between two carbon electrodes. All the synthesis methods mentioned were only theoretical, and acetylene was a rare and expensive gas until a cheap method was developed for producing calcium carbide by calcining a mixture of coal and quicklime: CaO + 3C = CaC 2 + CO. This happened at the end of the 19th century.

Then acetylene began to be used for lighting

. In a flame at high temperatures, this gas, containing 92.3% carbon (this is a kind of chemical record), decomposes to form solid carbon particles, which can contain from several to millions of carbon atoms. Heating strongly in the inner cone of the flame, these particles cause the flame to glow brightly - from yellow to white, depending on the temperature (the hotter the flame, the closer its color is to white).

Acetylene torches

gave 15 times more light than ordinary gas lamps that illuminated the streets. Gradually they were replaced by electric lighting, but for a long time they were used in small lamps on bicycles, motorcycles, and in horse-drawn carriages.

For a long time, acetylene for technical needs (for example, at construction sites) was obtained by “quenching” carbide with water. Acetylene obtained from technical calcium carbide has an unpleasant odor due to impurities of ammonia, hydrogen sulfide, phosphine, and arsine.

Acetylene today: methods of production

In industry, acetylene is often produced by the action of water on calcium carbide.

Methods for producing acetylene from natural gas - methane are now widely used:

electrocracking (a stream of methane is passed between the electrodes at a temperature of 1600°C and quickly cooled to prevent the decomposition of acetylene);

thermal oxidative cracking (incomplete oxidation), where the heat of partial combustion of acetylene is used in the reaction.

Application

Acetylene is used:

- for welding and cutting metals,

- as a source of very bright, white light in free-standing lamps, where it is obtained by the reaction of calcium carbide and water,

- in the production of explosives,

- for the production of acetic acid, ethyl alcohol, solvents, plastics, rubber, aromatic hydrocarbons.

Properties of acetylene

In its chemically pure form, acetylene has a weak ethereal odor. Technical acetylene, due to the presence of impurities in it, in particular hydrogen phosphide, has a sharp, specific odor. Acetylene is lighter than air. Acetylene gas is a colorless gas with a molecular weight of 26.038.

Acetylene is able to dissolve in many liquids. Its solubility depends on temperature: the lower the temperature of the liquid, the more it is able to “take up” acetylene. In the practice of producing dissolved acetylene, acetone is used, which at a temperature of 15 ° C dissolves up to 23 volumes of acetylene.

The content of hydrogen phosphide in acetylene must be strictly limited, since at the moment of formation of acetylene in the presence of air at high temperatures, spontaneous ignition can occur.

Acetylene is the only gas widely used in industry and is one of the few compounds whose combustion and explosion are possible in the absence of oxygen or other oxidizing agents.

Back in 1895, A.L. Le Chatelier discovered that acetylene, when burned in acid, produces a very hot flame (up to 3150°C), so it is widely used for welding and cutting refractory metals. Today, the use of acetylene for gas-flame processing of metals is experiencing strong competition from more accessible combustible gases (natural gas, propane-butane, etc.). However, the advantage of acetylene is its highest combustion temperature. In such a flame, even thick pieces of steel melt very quickly. That is why gas-flame processing of critical components of mechanical engineering structures is carried out only with the help of acetylene, which ensures the highest productivity and quality of the welding process.

In addition, acetylene is widely used in the organic synthesis of various substances - acetaldehyde and acetic acid, synthetic rubbers (isoprene and chloroprene), polyvinyl chloride and other polymers.

OPENING HISTORY

NAME OF ACETYLENE ACCORDING TO IUPAC NOMENCLATURE

PHYSICAL CHARACTERISTICS

STRUCTURAL FORMULA OF ACETYLENE

CHARACTERISTICS OF THE CLASS OF ORGANIC COMPOUNDS OF ACETYLENE

REACTIONS FOR PRODUCING ACETYLENE

CHARACTERISTIC CHEMICAL REACTIONS OF ACETYLENE

AREAS OF APPLICATION OF ACETYLENE

IMPACT OF ACETYLENE ON THE HUMAN BODY AND THE ENVIRONMENT

LIST OF REFERENCES USED

OPENING HISTORY

Acetylene was first produced in 1836 by Edmund Davy, cousin of the famous Humphry Davy. He reacted water on potassium carbide: K2C2 + H2O=C2H2 + 2KOH and obtained a new gas, which he called hydrogen bicarbonate. This gas was mainly of interest to chemists from the point of view of the theory of the structure of organic compounds. One of the creators of the so-called theory of radicals, Justus Liebig, called a group of atoms (i.e. radical) C2H3 acetyl.

In Latin, acetum means vinegar; the acetic acid molecule (C2H3O+O+H, as its formula was written then) was considered as an acetyl derivative. When the French chemist Marcelin Berthelot in 1855 managed to obtain “hydrogen bicarbonate” by several methods at once, he named it acetylene. Berthelot considered acetylene to be a derivative of acetyl, from which one hydrogen atom was removed: C2H3 - H = C2H2. First, Berthelot obtained acetylene by passing vapors of ethylene, methyl and ethyl alcohol through a red-hot tube. In 1862 he succeeded in synthesizing acetylene from the elements by passing hydrogen through a voltaic arc flame between two carbon electrodes. All the synthesis methods mentioned were only theoretical, and acetylene was a rare and expensive gas until a cheap method was developed for producing calcium carbide by calcining a mixture of coal and quicklime: CaO + 3C = CaC2 + CO. This happened at the end of the 19th century.

Then acetylene began to be used for lighting. In a flame at high temperatures, this gas, containing 92.3% carbon (this is a kind of chemical record), decomposes to form solid carbon particles, which can contain from several to millions of carbon atoms. Heating strongly in the inner cone of the flame, these particles cause the flame to glow brightly - from yellow to white, depending on the temperature (the hotter the flame, the closer its color is to white).

Acetylene torches produced 15 times more light than conventional gas lamps that illuminated the streets. Gradually they were replaced by electric lighting, but for a long time they were used in small lamps on bicycles, motorcycles, and in horse-drawn carriages.

For a long time, acetylene for technical needs (for example, at construction sites) was obtained by “quenching” carbide with water. Acetylene obtained from technical calcium carbide has an unpleasant odor due to impurities of ammonia, hydrogen sulfide, phosphine PH3, arsine AsH3.

NAME OF ACETYLENE ACCORDING TO IUPAC NOMENCLATURE

According to the IUPAC nomenclature, when constructing the names of alkynes in the names of the corresponding saturated hydrocarbons, the suffix -an is replaced by the suffix -in. To indicate the position of the triple bond and substituent groups, the chain is numbered in the same way as in the corresponding alkenes. Ethine can also be called trivially - acetylene.

PHYSICAL CHARACTERISTICS

Under normal conditions, it is a colorless gas, slightly soluble in water, lighter than air. Boiling point? 83.8 °C. When compressed, it decomposes explosively; it is stored in cylinders filled with kieselguhr or activated carbon impregnated with acetone, in which acetylene dissolves under pressure in large quantities. Explosive. Cannot be released into the open air. C2H2 is found on Uranus and Neptune.

STRUCTURAL FORMULA OF ACETYLENE

CHARACTERISTICS OF THE CLASS OF ORGANIC COMPOUNDS OF ACETYLENE

Acetylene belongs to the class of alkynes.

Alki ?nes (otherwise acetylene hydrocarbons) are hydrocarbons containing a triple bond between carbon atoms, forming a homologous series with the general formula CnH2n-2. The carbon atoms at the triple bond are in a state of sp-hybridization.

Alkynes are characterized by addition reactions. Unlike alkenes, which undergo electrophilic addition reactions, alkynes can also undergo nucleophilic addition reactions. This is due to the significant s-character of the bond and, as a consequence, the increased electronegativity of the carbon atom. In addition, the high mobility of the hydrogen atom at the triple bond determines the acidic properties of alkynes in substitution reactions.

Alkynes resemble the corresponding alkenes in their physical properties. Lower (up to C4) are colorless and odorless gases that have higher boiling points than their analogues in alkenes. Alkynes are poorly soluble in water, but better in organic solvents.

acetylene reaction compound formula

REACTIONS FOR PRODUCING ACETYLENE

In the laboratory, acetylene is produced by the action of water on calcium carbide.

2 H2O = C2H2? + Ca(OH)2

as well as during the dehydrogenation of two methane molecules at temperatures above 1400 °C:

CH4 = C2H2? +3H2?

CHARACTERISTIC CHEMICAL REACTIONS OF ACETYLENE

Basic chemical reactions of acetylene (addition reactions):

Basic chemical reactions of acetylene (addition reactions, dimerization, polymerization, cyclomerization).

AREAS OF APPLICATION OF ACETYLENE

Acetylene is used:

for welding and cutting metals,

as a source of very bright, white light in free-standing lamps, where it is produced by the reaction of calcium carbide and water (see carbide lamp),

in the production of explosives (see acetylenides),

for the production of acetic acid, ethyl alcohol, solvents, plastics, rubber, aromatic hydrocarbons,

to obtain carbon black,

in atomic absorption spectrophotometry during flame atomization,

in rocket engines (together with ammonia).

IMPACT OF ACITELENE ON THE HUMAN BODY AND THE ENVIRONMENT

Because acetylene is soluble in water and its mixtures with oxygen can explode over a very wide range of concentrations, it cannot be collected in gasometers.

Acetylene explodes at temperatures around 500 °C or pressures above 0.2 MPa; CPV 2.3-80.7%, auto-ignition temperature 335 °C. Explosiveness is reduced when acetylene is diluted with other gases, such as nitrogen, methane or propane. When acetylene comes into contact with copper and silver for a long time, copper and silver acetylenides are formed, which explode upon impact or increased temperature. Therefore, when storing acetylene, materials containing copper (for example, cylinder valves) are not used.

Acetylene has a weak toxic effect. For acetylene, the maximum permissible concentration limit is normalized. = MPC s.s. = 1.5 mg/m3 according to hygienic standards GN 2.1.6.1338-03 “Maximum permissible concentrations (MAC) of pollutants in the atmospheric air of populated areas.”

MPCr.z. (working area) is not established (according to GOST 5457-75 and GN 2.2.5.1314-03), since the concentration limits of flame distribution in a mixture with air are 2.5-100%.

It is stored and transported in white steel cylinders filled with an inert porous mass (for example, charcoal) (with a red lettering “A”) in the form of a solution in acetone under a pressure of 1.5-2.5 MPa.

LIST OF REFERENCES USED

1.Newland Y., Vogt R., Chemistry of acetylene, Inizdat, 1947.

.Fedorenko N.P., Methods and economics of acetylene production, Chemical Science and Industry, 3, vol. 1, 1956.

.Fedorenko N.P. Chemistry and chemical technology, No. 3, vol. I, 1956.

Tutoring

Need help studying a topic?

Our specialists will advise or provide tutoring services on topics that interest you.

Submit your application indicating the topic right now to find out about the possibility of obtaining a consultation.

For gas-flame work, it is necessary to transfer heat from the flame to the metal in an amount sufficient for specific work conditions. Combustible gases usually burn in a mixture with oxygen. The highest temperature is acetylene-oxygen flame (3200°C), which allows the use of acetylene in any type of gas-flame processing of metals. The intensity of flame combustion is determined by the product of the normal combustion rate and the heat of combustion of the mixture. Acetylene has the highest “burning intensity”, which for a mixture of stoichiometric composition is 27,700 kcal/(m 2 *s).

Acetylene

Acetylene belongs to the group of unsaturated hydrocarbons of the C n H 2n-2 series. . It is a colorless flammable gas with a specific odor; due to the presence of impurities in it - hydrogen phosphorous, hydrogen sulfide, etc. the density of acetylene at 20 ° C and 760 mm Hg. Art. equal to 1.091 kg/m3; at 0°C and 760 mm Hg. Art. – – density 1.171 kg/m3. Acetylene is lighter than air; density compared to air density 0.9; molecular weight 26.038. The critical point for acetylene is characterized by a saturated vapor pressure of 61.65 kgf/cm 2 and a temperature of 35.54°C. At 760 mm Hg. Art. and a temperature of –84°C, acetylene turns into a liquid state, and at a temperature of –85°C, it solidifies.

Acetylene is the only gas widely used in industry and is one of the few compounds whose combustion and explosion are possible in the absence of oxygen or other oxidizing agents. Acetylene is a highly endothermic compound; the decomposition of 1 kg of acetylene releases more than 2000 kcal, i.e. approximately 2 times more than the explosion of 1 kg of solid explosive TNT. The auto-ignition temperature of acetylene ranges from 500 to 600°C at a pressure of 2 kgf/cm2 and decreases noticeably with increasing pressure; Thus, at a pressure of 22 kgf/cm2, the auto-ignition temperature of acetylene is 350°C, and in the presence of catalysts such as iron powder, silica gel, activated carbon, etc., the decomposition of acetylene begins at 280 – 300°C. The presence of copper oxide reduces the auto-ignition temperature to 246°C. Under certain conditions, acetylene reacts with copper to form explosive compounds; Therefore, in the manufacture of acetylene equipment, it is prohibited to use alloys containing more than 70% Cu.

The explosive decomposition of acetylene, as a rule, begins with intense heating at a speed of 100 – 500°C/s. With slow heating, the polymerization reaction of acetylene occurs, which releases heat, which, as a rule, at temperatures above 530°C entails the explosive decomposition of acetylene. The lower limit pressure at which decomposition of acetylene is possible is 0.65 kgf/cm 2. Explosion limits for acetylene are wide (Table 2). The most dangerous are mixtures of acetylene with oxygen of stoichiometric composition (~30%). The velocities of flame propagation and detonation reach their greatest value at a ratio of acetylene and oxygen of 1:2.5 and are respectively equal to 13.5 and 2400 m/s under normal conditions. The pressure generated during an acetylene explosion depends on the initial parameters and the nature of the explosion. It can increase by approximately 10 - 12 times compared to the initial one during an explosion in small vessels and can be increased by 22 times with the detonation of pure acetylene and 50 times with the detonation of an acetylene-oxygen mixture.

In the gas-flame processing of metals, acetylene is used either in a gaseous state when produced in portable or stationary acetylene generators, or in a dissolved state. Dissolved acetylene is a solution of acetylene in acetone distributed evenly in a porous filler under pressure. The solubility of acetylene depends on temperature and pressure. The porous mass in the cylinder ensures the dispersal of acetylene throughout the entire volume and localization of the explosive decomposition of acetylene. In the absence of a porous mass in the cylinder, the initiated explosive decomposition of acetylene dissolved in acetone occurs at a pressure below 5 kgf/cm2. Not only bulk porous masses can be used as porous fillers, but also cast porous masses, which have found application abroad.

The physicochemical parameters of gaseous and dissolved technical acetylene are specified by GOST 5457 - 75. Based on the content of the permissible amount of impurities, dissolved, dissolved and gaseous acetylene is distinguished; the permissible content of impurities (in volume fractions) is respectively equal to:

- air and other gases poorly soluble in water - no more than 0.9, 1.0, 1.5;

- hydrogen phosphide – 0.01; 0.04; 0.08;

- hydrogen sulfide – 0.005; 0.05; 0.15;

- water vapor at 20°C and 760 mm Hg. Art. – 0.5; 0.6.

Technical dissolved acetylene is transported in steel cylinders. The permissible maximum pressure in cylinders should not exceed 13.4 kgf/cm 2 at a temperature of –5°C and a pressure of 760 mm Hg. Art. and 30 kgf/cm 2 at a temperature of +40°C and a pressure of 760 mm Hg. Art. The residual pressure in the cylinder with the same parameters should not be less than 0.5 and 3.0 kgf/cm 2, respectively.

For gas-flame processing of metals, along with acetylene obtained from calcium carbide, pyrolysis acetylene is used, obtained from natural gas by thermal-oxidative pyrolysis of methane with oxygen. Pyrolysis acetylene is also stored and transported in cylinders in dissolved form. The filler and solvent for pyrolysis acetylene are the same as for calcium carbide acetylene.

When using dissolved acetylene, compared to gaseous acetylene, the highest coefficient of carbide utilization, cleanliness of the welder's workplace, stable operation of the equipment and operational safety are ensured. The main raw material for the production of acetylene, used in the gas-flame processing of metals, is calcium carbide. Calcium carbide is produced in electric furnaces by reacting calcined lime with coke or anthracite. Molten calcium carbide is poured into molds where it solidifies; then it is crushed in lump crushers and sorted according to the size of the pieces in accordance with GOST 1460. Acetylene is obtained as a result of the decomposition (hydrolysis) of calcium carbide with water. The actual “liter volume” of acetylene from 1 kg of technical carbide at 20°C and 760 mm Hg. Art. does not exceed 285 l and depends on carbide granulation. As the size of carbide pieces increases, the displacement increases, but the rate of decomposition decreases, i.e., the duration of carbide decomposition increases (Table 1).

The content of hydrogen phosphide in acetylene by volume is not more than 0.08%, the content of sulfide sulfur is not more than 1.2%. GOST 1460 also stipulates the permissible number of pieces of calcium carbide of other sizes in batches of the specified granulation. The large thermal effect of the carbide decomposition reaction creates the danger of severe overheating. Without heat removal, during the interaction of a stoichiometric amount of calcium carbide and water, the reaction mass is heated to 700 – 800°C. The decomposition of carbide with insufficient cooling and especially in the presence of air can lead to an explosion, so the process must be carried out with a significant excess of water. To decompose 1 kg of carbide, 5–20 liters of water are required. Particular attention must be paid to the presence of carbide dust in the carbide. Dust decomposes almost instantly; due to instant heating, an acetylene explosion may occur. Therefore, dust processing in conventional generators not suitable for dust use is not permitted. If the dust content is significant, calcium carbide is sifted through a sieve with cells with a diameter of 2 mm before loading into the generator. The accumulated dust should be decomposed in the open air in a special vessel with a capacity of at least 800 - 1000 liters with vigorous stirring, while simultaneously pouring out no more than 250 g of carbide dust. The water should be changed after decomposition of dust in quantities up to 100 kg.

Calcium carbide is transported and stored in iron drums with a wall thickness of at least 0.51 mm and a weight of 50 - 130 kg. The side surface of the drums is made corrugated for greater rigidity. Calcium carbide intensively absorbs moisture even from the air, so if the container is poorly sealed, acetylene may form directly in the drum. The tightness of the drums should be carefully checked; When transporting drums in open vehicles, it is necessary to cover the drums with a tarpaulin. If damage to the drum is detected, the carbide must be poured into another sealed container.

When servicing stationary generators, carbide from the drums is poured into special receiver-hoppers. Opening of drums at the station is usually mechanized. For these purposes, machines are used in which the top cover is cut with a special cutting roller or wedge knives. The knives and roller are made of non-sparking material. In addition, oil or nitrogen is supplied to the cutting site.

Transportation of calcium carbide in drums for stationary generators with a capacity of over 20 m 3 /h is not economically justified, since unpacking the drums takes considerable time; a large amount of empty containers accumulates, which cannot be reused; the loss of carbide due to its crushing during rolling of drums and subsequent screening from dust is significant. Therefore, the container method of transporting and storing carbide for stationary installations can be considered the most promising. When flame processing of aluminum, brass, lead and other metals with a melting point lower than the melting point of steel, it is advisable to use not acetylene as a combustible gas, but gases that are acetylene substitutes or liquid combustibles. The main physical and thermal properties of combustible gases are given in table. 2.

Table 1. Physico-chemical parameters of calcium carbide

Table 2. Basic physical and thermal properties of combustible gases

|

Name of flammable gas and chemical formula |

Lower calorific value at 20°C and 760 mm Hg. st., kcal/m |

Flame temperature of the mixture with oxygen, °C |

Acetylene replacement rate |

Density at 20°C and 760 mm Hg. Art., kg/m 3 |

Critical pressure, kgf/cm 2 |

Temperature, °C |

Explosion limits, % of fuel content in the mixture |

The optimal ratio between oxygen and other fuels in the mixture |

Relative speed of flame propagation with air |

|||

|

critical * 1 |

melting |

with air |

with oxygen |

|||||||||

|

Acetylene C 2 H 2 |

||||||||||||

|

Hydrogen H 2 |

||||||||||||

|

Methane CH 4 |

||||||||||||

|

Ethane C 2 H 6 |

||||||||||||

|

Propane C 3 H 8 |

||||||||||||

|

Butane C 4 H 10 |

||||||||||||

|

Propane-butane |

||||||||||||

|

Ethylene C 2 H 4 |

||||||||||||

|

Carbon monoxide CO |

||||||||||||

|

Shale gas * 2 |

||||||||||||

|

Coke oven gas * 2 |

||||||||||||

|

Natural gas * 2 (methane 98%) |

||||||||||||

|

Petroleum (associated) gas |

||||||||||||

|

City gas * 2 |

||||||||||||

|

Pyrolysis gas |

||||||||||||

|

MAPP or MAF |

||||||||||||

|

Gasoline vapors (~С 7 Н 15) |

10 thousand kcal/kg |

0.7-0.74 kg/l |

||||||||||

|

Kerosene vapor (~С 7 Н 14) |

10 thousand kcal/kg |

0.79-0.82 kg/l |

||||||||||

*1 The critical temperature is the temperature above which a gas does not transform into a liquid state at any pressure.

*2 For flammable gas mixtures, the data given refers to the average composition of these gases.

The wide range of changes in density, flame temperature and heat of combustion is explained by the changing chemical composition of these gases, depending on the deposit or place of production.

Methyl acetylene propadiene MAPP(widely used in the USA) - a mixture of flammable gases; Its physical properties are close to propane. The explosive limits of MAPP in a mixture with air are 3.4 - 10.8%, in a mixture with oxygen 2.5 - 60%. Mixtures of methyl acetylene and propadiene are thermodynamically unstable, so a stabilizer is added to the MAPP composition. The decomposition of methyl acetylene, similar to acetylene, occurs with a large release of heat. The flame temperature of MAPP (2900°C) is close to the temperature of acetylene. MAPP is used for oxygen cutting and welding and other gas-flame processes.

MAF fuel- methyl acetylene propadiene fraction is a waste from olifin production, as well as a waste from the production of ethylene and monovinylacetylene. This fraction contains 48 - 75% mixture of methyl acetylene and propadiene and stabilizers: 3% propylene, 15% propane, 7% other hydrocarbons. Explosion limits for MAF are the same as for MAPP. The MAF is insensitive to shock. MAF cylinders do not explode when located next to a burning cylinder. The mixture is inert at temperatures up to 215°C and pressure up to 20 kgf/cm 2 . Upon contact with copper, explosive compounds are formed - copper acetylenides. The MAF flame propagation speed is 470 cm/s. The capacity of cylinders for liquefied gases is 40 or 55 dm 3; wall thickness 3 mm. The maximum operating pressure (kgf/cm2) in cylinders for liquefied gases is different: for propane no more than 16, for propylene 20, for butane and butylene 3.8. The filling coefficient of cylinders with liquefied gases (in kgf/m 3) will accordingly be equal to: 425 for propane, 445 for propylene, 448 for butane and 526 for butylene. The filling coefficient indicates the mass of gas in kg per 1 m 3 of cylinder capacity and should not exceed the values specified for each gas.

Turkic group of languages: peoples, classification, distribution and interesting facts Turkic language family of peoples

Turkic group of languages: peoples, classification, distribution and interesting facts Turkic language family of peoples Acetylene is the gas with the highest flame temperature!

Acetylene is the gas with the highest flame temperature! Clothes design (cut) system “M”

Clothes design (cut) system “M” What are some ways to preserve wild animals and plants?

What are some ways to preserve wild animals and plants? Literature test on the topic "Pantry of the Sun" (M

Literature test on the topic "Pantry of the Sun" (M Herbs: types of herbs, culinary uses and flavor combinations

Herbs: types of herbs, culinary uses and flavor combinations Present tenses (Simple, Continuous, Perfect, Perfect Continuous)

Present tenses (Simple, Continuous, Perfect, Perfect Continuous)