Technology for preparing yeast dough using a straight method and products made from it. Yeast sponge dough Preparation of products from yeast sponge dough

In the confectionery shops of public catering establishments, sponge and non-spread methods of dough preparation are used. The cooking method is selected depending on the amount of baking added. If the yeast dough contains a small amount of baking, then all products are kneaded at the same time.

To prepare yeast dough, use finely ground flour, premium or first grade. The quality of the products depends on the quality of the flour.

In rich thick dough, unfavorable conditions for fermentation are created, since a high concentration of sugar and oil inhibits the vital activity of yeast cells, fermentation proceeds sluggishly and gluten is formed of poor quality. In order to create conditions for normal fermentation by the yeast, the dough is first kneaded liquid and flour, water, yeast and a little sugar are added to its composition. This part of the dough is called dough, and the cooking method is called sponge dough. After the dough has fermented well, baking and the rest of the flour are added to it. The method of preparing the dough when all the products are put into the dough at the same time is called straight. The more baking is added to the dough, the less water and more yeast is taken.

The preparation of yeast dough is based on the ability of yeast to ferment sugars in flour into alcohol with the formation of carbon dioxide. The dough is not only loosened by carbon dioxide, but also, as a result of the vital activity of various microorganisms, acquires new taste qualities. This type of dough is sometimes called sour dough. After kneading through the fermentation and baking process, complex chemical changes occur in the dough that change the taste of the dough and increase its volume.

Starch grains swell and, under the action of enzymes contained in flour, decompose into simpler substances - dextrins and sugar, i.e. starch is saccharified. Part of the starch, under the action of flour and yeast enzymes, breaks down into simple sugar - glucose. Yeast ferments flour sugars for 1.5-2 hours. Under the action of an enzyme, the sugar contained in flour is converted into glucose and fructose.

The composition of yeast dough includes sugar (from 1 to 11% of the dough weight). Beet sugar, or sucrose, is also broken down by yeast into simpler sugars - glucose and fructose.

Fermented sugars turn into alcohol and carbon dioxide. The release of carbon dioxide and alcohol occurs throughout the entire thickness of the dough. The gas bubbles gradually expanding, stretch the gluten, the dough becomes porous and greatly increases in volume. Fermentation occurs best at a temperature of 30 degrees.

During fermentation, the dough acquires a sour taste, since lactic acid bacteria develop in it along with yeast, which are capable of fermenting sugars to form lactic acid.

The presence of lactic acid in the dough prevents the development of butyric and putrefactive bacteria, and also gives the products a pleasant taste. Lactic acid promotes the swelling of proteins and the production of products with greater rise.

Yeast fungi and lactic acid bacteria in the dough are almost motionless and, having used all the nutrients around them, gradually cease their vital activity. The carbon dioxide formed around them depresses them, and as a result, the fermentation process slows down and may stop completely. To restore the rate of fermentation, knead the dough.

When kneading, excess carbon dioxide is removed, the dough is enriched with air oxygen, and yeast fungi move throughout the entire volume of the dough. Kneading creates finer, more uniform porosity in the dough. The dough is kneaded two or three times. Yeast and lactic acid bacteria are evenly distributed in the dough and move to other more nutritious areas. After kneading, the rate of fermentation increases, and the dough again increases in volume. The number of kneads is determined by the quality of the gluten and the thickness of the dough. The thicker the dough and the stronger the gluten, the more kneading is done. Liquid dough and dough with weak gluten are usually prepared without kneading. Dough prepared with kneading is usually higher in quality than dough prepared without kneading. But a large number of warm-ups are harmful. If the number of kneads is too high, excess lactic acid accumulates in the dough, since it does not evaporate during kneading. Excess lactic acid prevents further development of yeast, and after the next kneading the dough will remain weakly loosened, this sharply worsens the taste of the products and makes them too sour.

By the end of fermentation, a sufficient amount of lactic acid has accumulated, which determines the taste of the dough, and carbon dioxide, which loosens it.

The sponge method of preparing dough is used for products with a large amount of baked goods and consists of two stages of preparing the dough and kneading the dough after the end of fermentation of the dough. To prepare the dough, take 35-60% flour, 60-70% water and 100% yeast (according to the recipe). The requirements for the water temperature when making dough using the sponge method, as well as for the volume of dishes or bowl, are the same as for straight dough. The kneaded dough should have a temperature of 27-29*C.

Initially, heated water is poured into the mixture and yeast is diluted in it, flour is added and everything is mixed. To activate the yeast, you can add up to 4% sugar to the dough in relation to the weight of flour. The dough should have the consistency of thick sour cream. The surface of the dough is sprinkled with a thin layer of flour, the bowl is closed with a lid or covered with a cloth and placed in a warm place for 2-3 hours. The intensive fermentation process begins after 30-40 minutes, when uniform cracks appear on the surface of the dough, the surface of the dough becomes convex, and it begins to move away from the walls of the dish. After 2-3 hours, the dough increases in volume by 2-2.5 times and bursting bubbles appear on the entire surface. The readiness of the dough is determined by external signs: fermentation begins to subside, fewer and fewer bubbles appear on the surface, and the dough falls off a little. For dough with a large amount of baking and when making it from flour with weak gluten, a thicker dough is prepared. In thick dough, the fermentation process proceeds more slowly and more evenly, resulting in a stronger dough. The remaining water with salt and sugar dissolved in it, eggs, fat and aromatics are added to the fermented dough. Mix everything well and add the remaining flour, after sifting it. The duration of kneading with flour is 15 minutes. The temperature of the kneaded dough should be 29_32*C. During normal fermentation, the dough rises evenly, without breaking, within 2-2.5 hours. It is elastic and does not stick to your hands. During this time, perform 1-2 warm-ups. The acidity of the dough is up to 3*. The dough preparation diagram is shown in Fig. 4. Dough with “flavoring” is prepared when it contains a lot of fat and sugar, which retard the development of yeast, or when it is necessary to prepare dough with different amounts of baking from one main dough. This method consists in the fact that the baking is introduced into the dough prepared using the sponge method, not immediately, but in two steps. The second portion of baking is called “sweetening”; a little more flour is added to it. The dough and the dough with the dough are prepared as described above, but when kneading it is taken into account that the more butter, sugar and eggs the dough contains, the more flour needs to be left for “furnishing”. If the recipe calls for a lot of eggs, then some of them can be added to the dough and even to the dough. Approximately an hour after kneading the dough prepared without “padding” (when the dough has doubled in volume), do the first kneading and add the remaining ingredients, salt and sugar dissolved in water, and softened butter. For products baked in molds, the dough is prepared more liquid than for products baked on sheets. Processing the dough with the “batter” lasts 4-5 minutes, leaving small islands of unkneaded dough with butter, this ensures the normal development of yeast. After 30-40 minutes, do a second knead for 3-5 minutes and mold the products. 0Dough with a slow fermentation process is prepared using dough mixed with water or milk at a temperature of 10-15°C. The dough mixed in the evening is placed in a room whose temperature is 18-20°C, and the remaining flour is placed in a warm place. In the morning, eggs and sugar are heated on a steam table to 40-60*C and mixed with the dough and then with flour. At the end of kneading the dough, the warmed fats are added. After an hour, this dough is ready for cutting. Dough with an accelerated fermentation process is prepared with an increased amount of yeast (2-3 times more than normal) or by placing the dough in water at a temperature of 35 * C and making it a more liquid consistency than usual. The dough is kneaded more intensively and for a longer time. The following describes dough deficiencies caused by improper fermentation processes.

Table 12

|

Flaws |

Causes |

Fixes |

|

The dough is not suitable or the fermentation process is not intense enough The dough is too sweet or salty The dough is sour Reduced dough volume Formation of a dried layer |

The dough has cooled below 10°C. The dough is overheated and has a temperature above 55°C. Poor quality yeast Sugar or salt was added in excess of the norm, as a result of which the development of yeast was delayed The dough has fermented Insufficient warm-up The dough was fermented in a room with low relative humidity |

Heat the dough gradually to 30*C. Cool the dough to 30°C and add fresh yeast. Add good quality yeast to the dough Knead the dough without sugar or salt and combine with oversweetened or oversalted dough Knead the dough without yeast, using peroxided dough as a starter Knead the dough depending on the “strength” of the flour During fermentation, cover the dough with a lid or napkin. |

Cutting and baking dough

Cutting yeast dough consists of several operations: dividing, rolling, intermediate proofing, molding and final proofing. During cutting, fermentation in the dough continues, so in order to avoid spoilage, this process must be completed in a short time. There are several types of machines for cutting and rolling out dough. You can also cut the dough manually on a table with a wooden lid. After kneading, the finished dough is laid out on a table sprinkled with flour, a long piece of even thickness is cut with a knife or scraper, which is rolled into a long rope.

Its thickness depends on the size of the finished product; The larger the product, the thicker the tourniquet should be made. The tourniquet is taken in the left hand, and with the right hand, a portion of the dough is cut off with a knife, which is placed on the scales, while simultaneously throwing off the previously placed piece of dough. The mass of dough portions must be accurate; A slight deviation of up to +2.5g is allowed. Portions of the dough should weigh 12-15% more than the finished products, since baking and drying of the product occurs during baking and cooling. Weighed portions are lightly floured and placed on the table. Then take two pieces of dough and roll them with your palms on the table in a circular motion.

When rolling, you need to make sure that there is a little flour between your palms and the dough balls, which prevents the dough from sticking to your hands. There should be no flour between the ball and the table, so that when rolling, the sides of the ball stick a little to the table and the dough is pulled down from all sides, creating a so-called seam. The rolled balls are placed on a table, sawn with flour, and after an intermediate proofing of 5-6 minutes, different products or balls of dough are formed from them, seam down on a greased baking sheet, at such a distance from each other that when proofing and baking they increase in size. in volume, did not connect or deform. It is best to place the balls on a baking sheet in a checkerboard pattern.

In this case, you can place a larger number of products on the baking sheet and, in addition, they are evenly baked during baking. Proofing of molded products. During the cutting process, carbon dioxide is partially released from the dough and its volume decreases. In order for the dough to be again enriched with carbon dioxide and the volume of the molded products to increase, they are placed for proofing in a damp place with a temperature of 30*C, covered with a napkin so that the products do not become airy.

The molded products are placed in a fermentation cabinet or chamber with a temperature of 35-40*C and a relative humidity of 70-80%. Proofing lasts 25-40 minutes, depending on the activity of the yeast, air temperature and humidity of the room, the size of the products, the dough recipe, and the “strength” of the flour. The higher the humidity in the proofing chamber, the less time it takes to rise the products. Small products lose more carbon dioxide during molding and cool more, so they require longer proofing.

Products with a large amount of baked goods and low yeast activity also require longer proofing. The end of proofing is determined by the increase in the volume of products. The product should feel light and airy to the touch. If the proofing is insufficient, the products turn out small, are poorly baked, and the crust has tears. This occurs because at the first moment the products are placed in the oven, the temperature rises and the fermentation process occurs more intensively.

The products begin to increase in volume, the crust formed on their surface cracks. If the products are exfoliated for too long, then they turn out flat, blurry, without gloss or pattern. The finished semi-finished dough in pieces weighing up to 10 kg is cooled in refrigeration chambers at a temperature of 4-8*C. The surface of the dough is greased, this prevents the formation of a crust. Packaging, packing, labeling and transportation, acceptance and examination of semi-finished products are carried out in accordance with the technical conditions and technological instructions MRTU 28/6--69. Yeast dough is packaged in metal boxes greased with vegetable oil. The total storage period should not exceed 12 hours at a temperature of 4-8*C. When making products from chilled yeast dough, it is cut into pieces of the required mass, proofed and shaped.

Products that are manufactured in the workshop are sent for finishing and baking. Finishing of molded products. To give baked products a beautiful appearance, they are brushed with egg yolk or melange using a soft hair brush. The most beautiful gloss is obtained by brushing the product with egg yolk. To ensure that the egg mixture covers the products more evenly, lightly break it with a brush or whisk before use (but do not whip it into foam); It is best to strain the lubricant through a sieve. The egg can be mixed with a small amount of water, but in this case the gloss on the products will be less beautiful.

Wrap the products 5-10 minutes before placing them in the oven very carefully so as not to wrinkle them. During baking, a shiny crust forms on the products, which prevents gases from evaporating from the dough and thereby increases the volume of the product. Immediately after brushing the products with egg, they are sprinkled with chopped nuts, sugar, crackers or flour crumbs, or a mixture of these products. Baking products. Butter products that are not brushed with egg should be baked in ovens with humidifiers. As a result of the contact of the surface of the product with moist air, the starch on the surface gelatinizes, the dextrins partially dissolve and the liquid starch paste fills the surface of the product. After condensation stops, the layer of liquid paste quickly dehydrates, forming a film on the surface of the crust that gives the product a glossy appearance.

Steam is formed in the baking chamber 5-6 minutes after placing the products in the oven. Baking products in a humidified chamber increases their yield and improves quality. For each type of dough, certain baking modes are established, and in order to obtain products of good quality, they must be strictly observed. Therefore, pastry cabinets and ovens are equipped with a thermometer. It is very convenient to regulate the temperature in cabinets with electric and gas heating. It is important not only that they have a certain average temperature, but that it is distributed evenly, otherwise one part of the product will be ready and begin to burn, while the other will still be raw. In addition, if the bottom or one of the walls of the oven is colder than the others, then the moisture of the product will move to its colder part and a “hardening” may form, i.e. an unfried layer with high humidity. Small products made from yeast dough are baked at a higher temperature (260-280*C), since they warm up quickly and do not have time to rise while the crust is forming.

At high temperatures, products made from “weak” flour should be baked first, otherwise the dough will become too spread out; These products are baked at a lower temperature. Old products are also baked at high temperatures to maintain the shape of the product. Such baking increases worker productivity and increases oven throughput. Large products, rich and poorly loosened, are baked at a low temperature (200-220 C), since slow heating of the products contributes to their uniform baking. The larger the products and the more sugar and other baked goods they contain, the lower the baking temperature should be, otherwise the crust will char and the inside of the products will be raw.

During baking, the outside of the product “browns”, i.e. a brown crust forms. Its color depends on the amount of sugar and amino acids in the dough. Sweet dough quickly acquires an intense brown color during baking. Due to the loss of moisture and a certain amount of nutrients, confectionery products lose weight during baking. Cooling of products and their finishing. After baking, the products begin to dry out due to the fact that moisture partially evaporates from them.

The crust of the finished products taken out of the oven is almost waterless, but it cools quickly, and moisture from the crumb, as a result of the difference in concentrations and temperatures inside and outside the products, rushes to the crust. During cooling, the crust is moistened to approximately 12%. At this level, the humidity remains stable as it cools further. After baking, some products are sprinkled with powdered sugar or a mixture of sugar and vanilla powder, using a sieve (mesh diameter 0.5 mm) or gauze. Other products are lubricated with heated scented lipstick.

To obtain a good gloss, apply lipstick to the products when they have not yet completely cooled down. The top of the product is sprinkled with fried chopped almonds or other nuts. Below are the disadvantages of finished products made from yeast dough and the reasons that caused them.

Table 13

|

Flaws |

Causes |

|

The surface of the product is covered with cracks Products are blurry without a pattern Products are elastic with cracks, the crust is pale, tastes salty Products are pale, without color The products are dark brown, the crumb is sticky Products are pale with cracks, smell sour Product crumb with uneven porosity Products with “temper” Products on the sides have areas without crusts - “presses” |

Insufficient proofing Low oven temperature Products baked from peroxided dough The dough contains little salt or a lot of butter, long proofing There is a lot of salt in the dough There is little salt in the dough There is a lot of sugar in the dough Peroxided dough Insufficient dough turnover The dough is kneaded too thin The oven was not hot enough Seating of products too close |

Culinary products made from yeast dough. Technology for preparing yeast dough using sponge and straight methods. Biochemical, microbiological and colloidal processes occurring during dough fermentation. Preparation of yeast puff pastry. Dough for flour dishes and side dishes: pancakes, pancakes, dumplings, pancakes, pasties, noodles, etc. Minced meat for flour dishes for culinary products.

The importance of flour dishes and products in nutrition

Dough products include flour dishes, flour culinary products, rich bakery products, and flour confectionery products. They occupy a worthy place in Slavic cuisine.

In the process of producing flour products, considerable attention is paid to the organization of their centralized production, which makes it possible to mechanize many labor-intensive operations (kneading and rolling out dough, weaving creams, making lipstick, etc.), as well as the use of semi-finished industrial products.

The main component of all flour products is flour, on the basis of which this or that dough is prepared.

The products included in the recipe for dough products have a high energy value and are an important source of carbohydrates (starch, dietary fiber and sugars), fats (especially dough products), B vitamins, and valuable minerals. Their nutritional value is determined primarily by the chemical composition of the flour.

Grain products cover more than 1/2 of the body's need for carbohydrates and about 40% for proteins. However, flour proteins are incomplete, since essential amino acids are found in them in ratios that are far from optimal. They are especially deficient in lysine. Therefore, protein utilization is no more than 56%; adding milk and eggs to the dough or preparing culinary flour products with minced cottage cheese, meat and fish can significantly increase protein utilization. Flour proteins are also not absorbed well enough (by 75...89%). By giving products looseness and porosity, their digestibility can be increased.

The ratio of the most important ash substances in flour is unfavorable, but products such as milk, cottage cheese, as well as cabbage and fruit mince, which are part of many flour products, significantly improve their mineral composition, especially enrich them with calcium and phosphorus compounds in the required ratio. In addition, the proteins of the products included in the fillings (minced meat) of flour dishes and products complement the amino acid composition of flour proteins. Thus, in dumplings with cottage cheese and cheesecakes, the amino acid composition of proteins is close to optimal.

Thus, the ratio of calcium and phosphorus compounds in yeast dough for pies is close to 1:6 (with an optimal ratio of 1:1.5...2), and in pies with cabbage it is 1:1.8. The protein content in the dough for fried pies is about 5.1 g per 100 g of product, and in the same pies with meat it is about 13%.).

Classification of flour dishes and products

I. Confectionery

1. Butter bakery products (buns, muffins)

2. Flour confectionery shops (cakes, pastries, gingerbreads, gingerbreads, cookies, muffins, profiteroles, rolls, baba)

II. Culinary

1. Flour dishes

Boiled (noodles, dumplings, dumplings, dumplings)

Fried (pancakes, pancakes, pancakes)

2. Flour products (pies, pies, donuts, kulebyaki, kurniks, cheesecakes, pasties, pizza)

3. Bread products (toast, croutons)

4. P/f for serving dishes (vol-au-vents, tartlets, croutons).

Characteristics of raw materials and their preparation

To prepare the dough, various types of raw materials are used: the main ones - flour (wheat, oatmeal and other TYPES), sugar, butter or margarine, eggs or egg products (melange, egg powder) and auxiliary - leavening agents, dyes, flavors (vanillin, essences) , organic acids (citric, etc.), starch, etc.

Flour. In POP they use g.o. wheat flour of the highest and 1st grade. The most important indicators of flour that determine its technological properties are moisture content, gluten content and quality.

Humidity. In the recipes, the flour consumption for preparing the dough of the required moisture content and consistency is set for a basic moisture content of 14.5%. During storage and transportation, the moisture content of flour may change. When using flour whose humidity is above 14.5%, the amount of liquid in the recipe is reduced, and when the humidity is below 14.5%, it is increased. The amount of liquid in the recipe in these cases is reduced or increased by 1% for each percentage deviation of the flour moisture content from the base.

The second most important indicator of the technological properties of flour is its force, which depends on the quantity and quality of gluten.

Gluten - a swollen elastic mass consisting of two proteins contained in wheat flour - gliadin and glutenin. Many structural and mechanical properties of the dough and the water absorption capacity of flour depend on the quantity and quality of gluten. Depending on the amount of raw gluten, flour is divided into three groups:

To prepare different types of dough, flour with different contents of raw gluten is used:

Yeast puff pastry made from flour containing 36...40% gluten;

Custard, waffle, biscuit - 28...35%;

§ shortbread, butter - 25...28%.

Sometimes, in order to reduce the gluten content in the dough (to prepare biscuit dough), starch is added to the flour before kneading.

Not only the quantity of gluten is of great importance, but also its quality.

Good gluten, cream-colored, elastic, does not stick to your hands, and can absorb a lot of water. Flour with such gluten is called strong. Dough made from such flour retains its shape well during proofing and curing, is elastic, has a normal consistency, and retains carbon dioxide well during fermentation; the shell of dumplings and dumplings made from this dough does not burst, baked goods retain their shape well.

Poor adhesive, gray in color, sticky, sticky, low-elastic, crumbly. Flour with such gluten is called weak. The dough made from it does not retain moisture well, spreads out, the products do not retain their shape well, the dough is characterized by low gas-retaining ability.

The kneading mode, fermentation time and temperature, and the number of dough kneads during fermentation depend on the quantity and quality of gluten (i.e., on the strength of flour).

The amount of water in recipes for flour products is calculated for medium strength flour. If necessary, it can be changed in accordance with the results of experimental developments and trial baking or the results of laboratory research.

Before use, the flour is sifted to remove mechanical impurities, destroy lumps and saturate the flour with air. When mixing flour with water, a homogeneous dough with certain properties is formed. The process of dough formation is that gluten particles swell, connect with each other and form an internal framework in the dough, giving it the necessary structural properties.

Sugar gives products a sweet taste, increases their calorie content, and in small quantities accelerates the development of yeast. It affects the mechanical properties of the dough - it limits the swelling of gluten, as a result of which the water absorption capacity of flour decreases and the elasticity of the dough decreases. With an increased amount of sugar, the dough liquefies and the products turn out deformed.

Granulated sugar is usually used. It is pre-dissolved in water, the solution is filtered. The solubility of sugar depends on the temperature of the water. Up to 2 kg of sugar dissolves in 1 liter of cold water, and up to 5 kg in 1 liter of hot water.

Eggs increase the nutritional value of dough products, enriching them with proteins, biologically active lipids (phosphatides) and vitamins.

Eggs also perform technological functions: beaten whites give the dough porosity, yolks are a good emulsifier, which allows you to obtain a stable emulsion from water and fat (this property is used in the preparation of waffles and cookies). Fresh eggs, mellage and egg powder are used.

Melange is a frozen mixture of egg whites and yolks. Eggs are replaced with melange in a ratio of 1: 1. Thawed melange cannot be stored, so only the required amount is thawed.

Egg powder contains moisture 6...7%. To restore it, first add a little warm water (40..50 °C), stir well and then, continuing to stir, pour in the rest of the water. For 100 g of powder, take a total of 0.35 liters of water. Before use, the powder mixed with water is kept for about 30 minutes and then filtered. 10 g of egg powder and 30 g of water corresponds to one medium-sized egg.

Fats They give products a rich taste, friability and layering. Fat introduced into the dough in a plastic state is evenly distributed on the surface of the gluten, forming films. Proteins swell less, gluten becomes less elastic and breaks easily. Taking this into account, when kneading yeast dough, fat is added at the end of the kneading. When baking, fat retains air better and the products rise more*.

Fat introduced into the dough in a molten state is distributed in it in the form of drops and is poorly retained in the finished product, oozing out on the surface. With an increase in the amount of fat, the dough becomes crumbly; with a decrease, the plasticity and friability of the products deteriorate.

Yeast POP receives compressed and dry yeast. Fresh pressed yeast has a light cream or light gray color and a pleasant, slightly alcoholic odor. Their humidity is 11-12%. They dissolve easily in water. The lifting power of frozen yeast can be restored by gradually thawing it at a temperature of 3...8 ‘C. Before use, pressed yeast is carefully removed from the packaging, dissolved in warm water (30...35 ‘C) and filtered through a sieve.

Dry yeast comes in the form of powder, grains or tablets. They have a yellowish-gray color and a humidity of 8...9%. Before use, dry yeast is mixed with flour and diluted with warm water (25...27 C), after 1 hour it is used to prepare dough (for 100 g of dry yeast, take 1 kg of flour and 3 liters of water). Dry yeast is taken by weight 3 times less than fresh.

Organic acids. They promote the swelling of gluten, and therefore, to increase its elasticity, citric acid or vinegar is added when making some types of dough.

Dyes and flavors . The use of synthetic dyes in making dough is not allowed, so only saffron infusion is used. To prepare it, saffron powder is poured with boiled water or alcohol and left for 24 hours. After this, it is filtered and added when making yeast dough products and some types of muffins.

Vanilla, valyline, and spices (coril, cloves, nutmeg, etc.) are used as flavoring agents.

Formation of the test

When kneading, biological, colloidal, and physical processes occur. Biological transformation of proteins, carbohydrates and other dough components under the influence of the corresponding enzymes. In the formation of millet. dough, proteins play an important role

As a result of kneading, a homogeneous mass of flour, water and other components is obtained, which has special physical properties: elasticity, extensibility, elasticity.

The mechanism of dough formation can be represented as follows. When water is added to flour, its colloids—protein substances and starch, contained in the flour in the form of dry gels—swell. During the swelling of the protein, approximately 1/4 of the total absorbed water is bound by adsorption, the rest - osmatically. Swelling of proteins after kneading the dough occurs within 20-30 minutes. In this case, a colloidal aggregate is formed - gluten, which is important for the formation of the physical properties of the dough. The swollen protein substances form a skeleton of a spongy structure, which gives the dough extensibility and elasticity. Starch, the content of which in flour (65-80%) is several times higher than the protein content, binds water by adsorption in an amount of no more than 30% of its own mass.

Fiber, the amount of which depends on the type of flour, also absorbs a significant amount of water.

The amount of water added to standard moisture flour during dough production ranges from 35 to 165% of the flour weight. The moisture content of various types of dough and finished products made from them is standardized by technological documents.

Simultaneously with colloidal processes, enzymatic processes occur in the dough, as a result of which some proteins (protease and peptase enzymes) and some fats (lipase enzymes) are hydrolyzed. Amylolytic enzymes in flour convert some of the starch into dextrins (amylase enzyme) and maltose, and then maltose into glucose (maltase enzyme).

When kneading yeast dough and its subsequent fermentation, yeast enzymes (sucrase and maltase) ferment sucrose and maltose to monosaccharides, which then participate in alcoholic and lactic acid fermentation.

When baking, a characteristic external sign of changes in products made from yeast dough or from dough with chemical, mechanical leavening agents is a rapid increase in their volume, usually lasting no more than 5 minutes and stopping as a result of the formation of a crust and a change in the consistency of the dough inside the product. The volume of the baked product is 10-30% greater than the volume of the dough pieces after proofing and depends on the amount of gaseous substances formed as a result of the decomposition of chemical leavening agents or fermentation products in the yeast dough. Soda and ammonium begin to decompose with the release of carbon dioxide at 60-80°C.

The temperature of the surface layer of products quickly increases and at 100°C moisture begins to evaporate intensively from it. Due to the temperature difference, moisture moves from areas (from the outer layer), where the temperature is higher, to the inner layers of the crumb, where the temperature is lower (the phenomenon of thermal moisture transfer). As a result, the top layer gradually turns into an almost completely dehydrated crust with a temperature of 130-150’C. Its color and aroma are due to processes such as melanoid formation, dextrinization of starch, and caramelization of sugars.

In the inner layers of the product the temperature is close to 100°C. When heated above 70°C, gluten proteins denature and coagulate. In this case, the moisture absorbed by the proteins during kneading the dough is released and absorbed by the gelatinizing starch, i.e. moisture redistribution occurs. Denaturation of proteins and gelatinization of starch are the main processes that determine the transition of dough into crumb and the formation of a strong structure of products.

As a result of the loss of water due to evaporation, baked products have less mass than the products before baking. The ratio of the difference in the mass of the product before and after baking to the mass of the product before baking is called baking. Express it as a percentage and calculate it.

The baking quality of a particular dough is higher, the more moisture it loses during baking, i.e., the smaller and thinner the baked product and the longer the heat treatment; The higher the moisture content of the dough, the higher the baking.

The loss of mass when products cool is called shrinkage. The mass of the finished product is always greater than the mass of flour used to make the product. The ratio of the difference in the mass of the baked product and the flour taken during kneading to the mass of flour is called baking.

The higher the baking of a particular dough, the more water is added to the dough. Flour with high-quality gluten absorbs more moisture when kneading dough than flour with weak gluten; this also increases the baking of the product.

Test classification

Depending on the main type of raw material, the dough can be divided into two groups: with flour and without flour.

Flour dough is used for preparing flour dishes, culinary and confectionery products. Dough without flour (for example, protein-air - mainly for the preparation of confectionery products.

Depending on the method of leavening, flour dough is divided into yeast (sour) and unleavened (yeast-free).

Yeast dough can be prepared using sponge and straight methods. If, when cutting, the dough is sandwiched with butter or margarine, you get puff pastry.

Yeast (sour):

1.liquid (for pancakes, for pancakes);

2.thick (simple, rich);

Fresh (yeast-free):

1. flour: -thick (noodle, shortbread, unleavened butter, puff pastry, sponge cake, custard, almond-nut);

Liquid (for pancakes, waffle);

2.without flour (sugar-protein).

Yeast-free dough, according to the method of loosening, is in turn divided into several types:

Prepared with chemical leavening agents (shortbread, butter, waffle, gingerbread, etc.);

Prepared by whipping (sponge, puffed, almond);

Prepared by layering (puff paste);

Prepared using the custard method, in which all or part of the flour is boiled (custard).

Methods for loosening dough

1. Microbiological method. When kneading the dough, yeast is added, resulting in the fermentation of dough sugars (glucose, fructose, sucrose, maltose). The predominant type of fermentation is alcoholic.

Simultaneously with alcoholic fermentation, lactic acid fermentation occurs, caused by bacteria that enter during the dough kneading process from another type of raw material or from the air. In this case, lactic and other acids are formed - acetic, oxalic, tartaric.

As a result of the accumulation of carbon dioxide in the dough during fermentation during baking, a loosened porous structure is formed, which ensures sufficient porosity of the baked product. -

2. Chemical method. This method involves adding chemical leavening agents to the dough, most often sodium bicarbonate (baking soda) and ammonium carbonate, which, when heated to 60 °C, decompose to release carbon dioxide.

Sodium bicarbonate decomposes in the dough to form sodium carbonate. carbon dioxide and water. Sodium bicarbonate colors products yellowish and gives them a specific taste, especially noticeable when an excess amount of this baking powder is added.

High alkalinity gives products a salty-bitter taste. Ammonium carbonate decomposes in the dough, releasing ammonia, carbon dioxide and water.

A characteristic feature of the use of ammonium carbonate is the preservation of the white color of the dough and product after baking. When warm, the products have an ammonia smell, which disappears after cooling; When an excess amount of ammonium is added to the dough, the smell of ammonia remains in the products for a long time. To improve the taste of flour confectionery products, a mixture of these two types of raising agents is usually added.

3. Mechanical method. This method of leavening involves the use of emulsifying properties contained in various products (lecithin in egg products, casein in milk and dairy products, etc.). After beating the mixture of products included in the product recipe to obtain a well-dispersed emulsion, knead the dough by mixing the emulsion with flour.

To prepare puff pastry, a mechanical method is also used - repeated rolling out of the dough with layers of margarine or butter. Baking at high temperatures promotes intense vapor formation and separation of products.

In the absence of emulsifying substances in the products or when

their deficiency, emulsifiers are used. During the beating process, air penetrates into the mass of the product and saturates it in the form of small bubbles, enveloped in films of particles of the whipped product, and therefore the volume of the dough increases; this method of loosening is used to produce sponge cake, choux, protein and pancake dough .

4. Combined method loosening the dough (mechanical with the use of chemical leavening agents). It is used when making dough with a high baking content (for butter cake), when leavening cannot be achieved only by using an emulsion.

Preparation of yeast dough and products made from it.

Yeast dough, regardless of its consistency, can be prepared in two ways: straight and sponged. The first method is used mainly for products with a small amount of baked goods (sugar, fat, eggs), the second - for products with a large amount of baked goods.

At safe method, all raw materials are immediately kneaded into dough, which is fermented. During the fermentation process, the dough is kneaded 2-3 times. The end of fermentation is determined by external signs: the fermented dough increases in volume by 2.5 times, acquires a pleasant alcoholic smell, and the surface of the dough is convex.

At sponge In this method, first prepare the dough - a liquid dough without sugar and fat. After its fermentation, the rest of the raw materials are added and the dough is kneaded. Before the end of the kneading (2...3 minutes), add softened butter and margarine. Then the dough is left to ferment for 2...2.5 hours.

The prepared dough is cut and shaped (divided into pieces of the required mass and shaped).

After a short proofing (fermentation), the products are baked. To improve the appearance of the baked product, its surface is greased with egg, egg with milk or melange before baking.

Small products made from yeast dough are baked for 8...15 minutes at a temperature of 230...240 °C. At a higher temperature at the beginning of the process, products should be baked from weak flour, otherwise the dough will become too spread out; bake them at a lower temperature.

Large products, rich and poorly loosened, are baked for 20...50 minutes at a temperature of 200...220 °C. Slow heating promotes even baking of products. The larger the product and the larger the baked goods, the lower the baking temperature should be, otherwise the crust will char and the inside of the product will be raw.

The finished products are cooled at room temperature on wooden sheets.

Baked, fried pies, pies, kulebyaki, pies, cheesecakes, donuts, buns (school, vanilla, butter)

Yeast puff pastry. During production, two methods of loosening are used: using carbon dioxide, which is formed as a result of the activity of yeast, and by lubricating the rolled out layers of dough with margarine or butter. The process of running such a test consists of:

Preparation of yeast dough using a sponge or non-sponge method;

Lamination of dough;

Product molding;

Proofing, which is necessary since most of the carbon dioxide is removed when rolling out the dough and it takes time for it to accumulate again

When laminating, the temperature of the butter (or margarine) and the dough should be 20..22C. At this temperature, the butter does not melt and does not penetrate the dough, but forms plastic layers between them, which ensures good loosening and shaping of the products. If the product recipe includes a lot of sugar, then part of it is put into the dough when kneading, and part of it is ground with butter until a homogeneous plastic mass without lumps is obtained.

The yeast dough, cooled to 20...22C, is rolled out into a layer 1...2 cm thick, 2/3 of the layer is covered with butter or margarine, softened to the consistency of thick sour cream. Then the layer is folded in three so that you get two layers of butter and three layers of dough. The edges of this layer are pinched so that the oil does not leak out when rolling. After this, the layer is turned 180’, sandwiched with flour and rolled out again to a thickness of 1 cm. The flour is swept away from the surface, the layer is folded in four. There will be 8 layers of butter in the dough. When making dough with a large amount of butter, the prepared layer is folded in half again and rolled out again. That. The result is a dough with 16, 24 or 32 layers of butter. You cannot layer the dough any more, since the layers are very thin and can tear, as a result the layering will decrease and the dough will not separate into layers after baking.

Another way:

Pieces of dough weighing no more than 5 kg are cooled to 17... 18 C;

The chilled dough is rolled out into a layer 15...20 cm thick;

Lubricate half of the layer with softened butter (margarine);

The layer is folded in half and re-rolled;

Lubricate half of the layer with oil, let it sit for 20-30 minutes, fold it in half and roll it out to a thickness of 5...6 mm;

The rolled out layer is greased again with softened butter or margarine and products are formed from it. The temperature during lamination and cutting should be 20...22C. After cutting, the products are left to rest for 10..12 minutes at a temperature not exceeding 35 C so that the oil does not leak out.

Puff pastry products are baked at 210...250C. At a higher temperature, a dehydrated crust forms on the surface before the products are baked, so they will begin to burn. At a lower temperature, the products bake slowly and the oil may leak out.

Baking time for small-piece products is 8...10 minutes, kulebyak - 35...45 minutes.

Puff pastries of different shapes (envelope, triangle, book) are prepared from puff pastry dough: buns with nuts, kulebyaki, puff pastry with marzipan, puff pastry with jam, etc.

Dough for pancakes and pancakes prepared in a straight method with a liquid (for pancakes) or semi-liquid (for pancakes) consistency. When preparing dough for pancakes, salt and sugar are dissolved in a small amount of water or milk, pre-diluted yeast is added, the mixture is filtered, combined with the rest of the liquid, heated to a temperature of 35..40 'C, sifted flour is added, eggs are added and mixed until a homogeneous mixture is formed. masses. At the end, melted fat is added. To make baked products lighter and more porous, you can add beaten egg whites to the finished dough.

Pancake dough is sometimes prepared from a mixture of wheat and buckwheat flour, taken equally. Instead of buckwheat flour, you can use semolina. You can add vegetable purees.

The dough for pancakes is prepared in the same way as for pancakes, but with a thicker consistency. To prepare dough for pancakes, take 1.5 liters of liquid per 1 kg of flour, and 1 liter for pancakes.

Dough for dumplings, dumplings, homemade noodles. A very thick (steep) dough is prepared for these products. Take as much water as the flour can absorb due to gluten swelling. Products made from such dough are very dense and can only be boiled. To prepare the dough, dough mixing machines are used, into the bowl of which flour is poured, water (or a mixture of water and milk for dumplings) heated to 30...35 ° C, eggs, salt are added and the dough is kneaded until it becomes homogeneous. consistency. The prepared dough is left for 20...30 minutes, covered with a napkin or lid, to allow the gluten to swell and give the dough elasticity. When preparing a small amount of dough, sifted premium or 1st grade wheat flour is poured into a slide on a table with a wooden surface, a depression is made in the middle of the slide, into which water is poured with salt and eggs dissolved in it and the dough is kneaded. The ratio of flour and water for dough for dumplings and dumplings is 1: 0.35, for homemade noodles it is even less - 1: 0.2.

Batter for pancakes contains a large amount of liquid (the humidity of the finished dough is 66%), so the flour proteins swell quickly and well in it. This allows it to be loosened by mechanical beating, during which foam is formed. The viscosity of the dough is so high that it retains air bubbles, which expand during baking and give the products porosity. This dough requires flour with a medium gluten content.

To prepare pancake dough, place eggs, salt, sugar into the bowl of a whipping machine and beat quickly (you can use a whisk). Once the mass becomes homogeneous, pour in milk and add flour - 50% of the norm. Mix slowly in the machine to avoid splashing. Stirring the flour should not be interrupted even for a short time, otherwise the dough will turn out lumpy, uneven, and of poor quality. After the flour is completely mixed, add the rest of it in small portions and turn on the machine at high speed. Beat the finished dough for 2...3 minutes. If lumps have formed in the dough, strain it.

Minced meat

Minced meat prepared from cutlet meat in two ways. First - The cutlet meat is washed, cut into small pieces, fried in fat, then transferred to a deep bowl, adding broth or water and simmering until done. The finished meat is passed through a meat grinder along with sautéed onions. The flour sautéed with fat is diluted with the broth left over from poaching the meat and boiled. The white sauce is obtained, season the minced meat, add salt, pepper, finely chopped herbs and mix.

Second way. Cutlet meat, cut into small pieces, is passed through a meat grinder and fried on a baking sheet in a layer of no more than 3 cm, stirring occasionally. The finished meat is mixed with sautéed onions and once again passed through a meat grinder with a fine grid, seasoned with white sauce, salt, pepper, chopped herbs and mixed.

When preparing minced meat with egg, rice or rice and egg, appropriate products are added to the prepared minced meat

Minced liver. The offal (lung, heart, liver) is washed and cut into pieces. The heart and lung are boiled in salted water, the liver is fried. The finished offal is passed through a meat grinder, placed in a layer of no more than 2...3 cm on a baking tray preheated with fat and fried while stirring. Add sautéed onions, white sauce, salt, pepper to this mass and mix.

Minced fish Skinless and boneless fish fillets are cut into pieces and poached. The finished fish is chopped, sautéed onions, salt, pepper, chopped herbs, parsley, and white sauce are added. You can cook minced fish with rice, rice and vizig. Before boiling, dry viziga is soaked for 2-3 hours in cold water and boiled until completely softened. The finished viziga is passed through a meat grinder and then heated with melted margarine.

Minced potatoes with mushrooms or onions. The potatoes are boiled, pureed while hot, mixed with sautéed onions or boiled chopped mushrooms and onions.

Minced green onion with egg. The green onions are washed, finely chopped, combined with chopped eggs, melted margarine, salt, and chopped herbs.

Minced cabbage made from fresh and sauerkraut.

Minced mushroom. Dried porcini mushrooms are thoroughly washed, soaked and then boiled. The resulting broth is filtered and used to prepare the sauce. Boiled mushrooms are washed, passed through a meat grinder, lightly fried, sauteed onions, salt, pepper, white sauce are added and mixed thoroughly.

Minced apple. Sliced apples are sprinkled with sugar, water is added (20...30 g per 1 kg of apples) and cooked, stirring, over low heat until the mass thickens. Minced apples can be prepared without heat treatment; for this, chopped apples (with tender pulp) are sprinkled with granulated sugar and used as a filling.

Minced curd. The cottage cheese is passed through a grinding machine, eggs, flour, sugar, butter, and vanillin are added. This is how minced meat is prepared for cheesecakes, pies, and dumplings. For pancakes, add eggs, sugar to the pureed cottage cheese and mix.

Yeast dough

When preparing yeast dough, water (milk), sugar, salt, yeast, melange (eggs), flour, and butter are used.

The process of preparing yeast dough consists of two stages - kneading and baking.

Kneading - making yeast dough is based on the ability of yeast to ferment sugars in flour into alcohol, producing carbon dioxide. The dough is not only loosened by carbon dioxide, but also acquires a sour taste as a result of the activity of various microorganisms.

After kneading, the fermentation process undergoes complex chemical changes in the dough that change the taste of the dough and change its volume.

Yeast dough is prepared using straight and sponge methods.

With the safe method water or milk is heated to 26-30 degrees, yeast, salt and sugar are dissolved in the liquid, then eggs are added and sifted flour is added. Knead the prepared dough for 5-10 minutes, add melted butter at the end of kneading. The kneaded dough is covered with gauze and left to ferment in a warm place for 2.5-3.5 hours. During this time, knead the dough 2-3 times.

Pies with various minced meats, closed pies, cheesecakes and other products are prepared from straight dough.

The finished dough is cut as follows: transfer it to a table dusted with flour, cut off a piece of even thickness, roll it into a long rope and cut with a knife or tear off pieces of dough of the required mass, then form balls and after a short resting (5-8 minutes) produce final molding of products. It is advisable to cut the dough on tables with a wooden surface.

The formed product is left for final proofing. The duration of proofing ranges from 15 to 40 minutes and depends on a number of factors: dough recipe, flour strength, temperature conditions, humidity.

Products with a large amount of baked goods require long proofing. Dough with more moisture rises faster.

The main factors influencing the duration of proofing are temperature and relative humidity. The optimal conditions for proofing are air temperature 35-40°C and relative humidity 75-80%. These conditions are especially important for accelerated methods of preparing yeast dough.

After proofing, the products are brushed with egg and baked at the following temperature: small - 240-260 C for 8-15 minutes; large ones - 200-220°C for 20-50 minutes. Large products are pierced in several places before baking.

16. Technology for preparing yeast dough using the sponge method and products made from it.

With the sponge method of preparing dough, the dough is first prepared. To do this, pour water or milk heated to 26-30 degrees (60-70% of the intended liquid) into the dishes, add yeast, previously diluted in a small amount of water, and add part of the flour (35-50%). The dough is stirred until its consistency becomes homogeneous, and then covered with gauze or a towel and placed in a warm place to ferment for 3-3.5 hours.

When the dough rises and begins to fall, pour the remaining water into it (salt and sugar are pre-diluted in water or milk) and all other heated products, gradually add the remaining flour and knead for 5-10 minutes. At the end of mixing, add melted butter. The dough is placed in a warm place for fermentation, during which it is kneaded twice.

The finished dough is used to form products that are placed on oiled sheets. Then place for 20-30 minutes in a warm place (30-35 degrees) for proofing. To improve the appearance of the product, brush it with egg a few minutes before baking. Dough products are baked in the oven at a temperature of 180-200C.

Bread, homemade buns, Ukrainian donuts, kulebyaki.

Dough products are widely used in catering establishments. The nutritional value of dough products depends on their content of carbohydrates, proteins, fats and vitamins B and PP. Dough products have a high calorie content, have a pleasant appearance, taste, aroma and promote better absorption of other products.

Yeast dough. Yeast dough is prepared in two ways: straight and sponged.

The first method is used mainly for products with a small amount of baked goods (sugar, margarine, eggs), the second - for products with a large amount of baked goods.

Safe way. Water (or milk) heated to 30-35 °C is poured into the dough mixing machine, diluted and strained yeast, solutions of salt, sugar, eggs or melange are added and sifted flour is added. The dough is thoroughly kneaded. The resulting mass is stirred for several minutes. The readiness of the dough is determined by its homogeneity and the absence of lumps. In addition, well-kneaded dough easily comes off the hands and walls of the dishes. At the end of the kneading, add margarine, softened to the consistency of sour cream. Cover the bowl with a lid and leave for 3-4 hours in a warm room with a temperature of 30-40°C. During kneading, the dough is mixed well, while carbon dioxide is evenly distributed in the form of small bubbles, which later during baking ensures good porosity of the product.

The end of fermentation is determined by external signs: the fermented dough increases in volume by 2.5 times, acquires a pleasant alcoholic smell, and the surface of the dough is convex.

Oparny way. Preparing dough using the sponge method consists of two phases: preparing the dough (liquid dough) and preparing the dough after fermentation of the dough has finished. Knead the dough in the bowl of a dough mixing machine: add yeast, previously crushed and diluted in a small amount of warm water, into water or milk heated to 30-35°C (60-70% of the total amount), add part of the flour (35-60% of the total amount) , stir until smooth and leave for 2.5-3 hours to ferment in a room with a temperature of 35-40°C. The surface of the dough is sprinkled with flour, the bowl is covered with gauze or cloth and placed in a warm room for 2.5-3 hours for fermentation.

The prepared dough is divided into pieces of the required mass manually or using a dough divider.

Pieces of dough are formed into balls, then formed into products (buns, pies, pies, kulebyaki, etc.) and left to proof. The surface of the products is greased with a mixture of eggs, milk and butter. The most beautiful gloss is obtained by smearing the products with yolk. Lubricate the products 5-10 minutes before placing them in the oven very carefully so as not to wrinkle them. During baking, a shiny crust forms on the products, which prevents carbon dioxide from evaporating from the dough and thereby increases the volume of the products. The products are baked for 8-15 minutes at a temperature of 220-240? C. Large products, rich and poorly loosened, are baked for 20-50 minutes at a temperature of 200-220? C. Slow heating promotes even baking of products. The larger the product and the more baking it contains, the lower the baking temperature should be, otherwise the crust will char and the inside of the product will be raw.

The finished products are cooled at room temperature on wooden sheets. The crust of the products taken out of the oven is almost waterless, but it cools quickly, and the moisture from the crumb into; As a result of the temperature difference between the inside and outside of the product, it rushes to the crust. During cooling, the crust moistens by about 12%.

Pies, pies, cheesecakes, donuts, kulebyaki, etc. are prepared from yeast dough.

Preparation of the product. Kulebyaka. A rectangular sheet is rolled out from the sponge dough, minced meat, fish, cabbage is placed on it. The dough is rolled up so as to form an elongated roller, the edges above the minced meat are connected and pinched, and placed on the sheet with the seam down. The surface of the kulebyaki is greased with egg, and punctures are made in the dough to allow steam to escape.

Homemade bun. Balls weighing 107 g are formed from the dough prepared using the sponge method. when placed on a baking sheet, the distance between the dough balls should be 8-10 cm. After this, the baking sheet is placed in a warm, damp place for proofing. 5-10 minutes before baking, the buns are evenly brushed with egg using a brush, sprinkled with granulated sugar and baked at 230 °C for 10 minutes.

Cheesecake. Yeast dough for cheesecakes is prepared using a straight method. The finished dough is rolled out into a rope with a diameter of 3 cm, divided into pieces weighing 58 g and rolled into balls. They are placed on a pastry sheet at a distance of 6-8cm from each other and pressed lightly with your hand. After the 15th proofing, use a wooden pestle or the end of a rolling pin with a diameter of 5 cm to make a depression in the buns; The thickened edges are greased with egg, and minced meat or jam is released from the pastry bag into the recess. Cheesecakes with minced curd need to be greased with egg after filling with minced meat and proofing. Cheesecakes are baked at a temperature of 230-240 °C for 6-8 minutes.

Children's bun. Yeast dough is prepared from grade I wheat flour, balls are formed from it, placed on sheets greased with vegetable oil for 30-40 minutes and baked in a humidified chamber for 14-16 minutes at a temperature of 180-190 ° C.

Pie "Moscow". Open. Yeast dough is prepared using a straight method. The minced meat is sweet. Depending on the design, pies can be open, half-open or closed. For an open pie, roll a piece of dough into a ball, leave it for 5 minutes to proof, then roll it out into a layer 1 cm thick according to the size of the mold and baking sheet. The rolled out dough is transferred using a rolling pin onto a greased form and placed, leveling the edges. A layer of jam is applied to the surface of the formation. The edges of the pie are brushed with egg. The pies are defrosted, 5-10 minutes before baking, brushed with egg and baked for 30 minutes at a temperature of 220-230 °C.

Cupcake "May". The cake is baked from yeast sponge dough, placed in cylindrical molds greased with margarine and left to rise for 20-25 minutes at a temperature of 30 °C. After proofing, the surface of the product is greased with melange (egg), punctures are made with a pin in several places to a depth of 2-3 cm so that voids do not form under the crust, and baked. The top and sides of the chilled products are sprinkled with powdered sugar. Cupcakes are baked by weight and by the piece. The baking temperature for the cake is 190-200 °C, the baking time depends on the size of the product. Remove the cupcakes by shaking the pan slightly. If the cake sticks to the bottom or walls, pass a knife with a narrow blade between the cake and the pan and turn the pan upside down. The slightly burnt surface of the cake is cleaned with a grater. Sprinkle the surface of the cooled cake with powdered sugar.

Pancakes. For pancakes, prepare yeast-free dough. Salt and sugar are dissolved in a small amount of water or milk, pre-dissolved yeast is added, the mixture is filtered, combined with the rest of the water, heated to a temperature of 35-40 C, flour and eggs are added and mixed until a homogeneous mass is formed, then melted fat is added and mixed again . The kneaded dough is left in a warm place to ferment for 3-4 hours. During the fermentation process, the dough is kneaded. Pancakes are baked in cast iron pans on both sides. The thickness of the pancake must be at least 3 mm.

Pancakes. The dough is prepared in the same way as for pancakes, but much thicker. They bake on heated (cast iron) frying pans, thick-walled baking sheets or electric frying pans in the same way as pancakes, but the layer of dough is thicker and the dimensions are smaller. The dough is spread out with a spoon (pre-moistened with water so that the dough comes out better) or released from a pastry bag. Pancakes are baked on both sides. They can be deep fried. The thickness of the finished products must be at least 5-6 mm.

You can add finely chopped apples, washed raisins, etc. to the dough for pancakes. Pancakes are served with butter, sour cream, jam, marmalade, honey, jam, sugar, 3 pieces each. per serving.

School bun. Flour 3121, butter 94, vegetable oil 16, salt 47, yeast 31, water 1607. For lubrication: fat for sheets 25, melange for products 31. Yield 100 pcs. 40 g each. On a table dusted with flour, the finished dough is divided into pieces weighing 47 g and balls are formed, which are placed on pastry sheets, seam down, at a distance of 3-4 cm from each other. The duration of proofing of products in a warm, humid place is 25-30 minutes. 5-10 minutes before baking, the buns are greased with melange and baked at 250-270 °C for 8-10 minutes. Baking "Forest Round Dance" Flour 3900, granulated sugar 800, butter 670, melange 240, salt 50, yeast 100, vanillin 0.3, raisins 20, nuts 20. Yield 100 pcs. 50 g each. The dough is divided into pieces weighing 55 g. “Mushrooms” are formed from the pieces: an oval blank is rolled out up to 1 cm thick, then two “hats” are cut off from the oval on one side and on the other side. From the remaining part, 1.5-2 cm is cut off on one side and several cuts are made - “grass”, and then the remaining rectangle is cut diagonally - “legs”. All parts are connected so that you get two “mushrooms” with “grass” and glued together with melange. After proofing, they are greased with melange, and the “hats” are decorated with raisins and nuts. Bake at a temperature of 240-250 °C. Cheesecake Flour 3800, table margarine 200, melange 200, salt 40, yeast 100, water 1500. Minced curd or jam 3000. For lubrication: fat for sheets 25, melange 150. Yield 100 pcs. 75 g each. The finished dough is rolled out into a rope with a diameter of 3 cm, divided into pieces weighing 58 g and rolled into balls. They are placed on a pastry sheet at a distance of 6-8 cm from each other and pressed lightly with your hand. After proofing for 15 minutes, use a wooden pestle or the end of a rolling pin with a diameter of 5 cm to make a depression in the buns; the thickened edges are greased with egg, and minced meat or jam is released into the recess from a pastry bag. Cheesecakes with minced curd need to be greased with egg after filling with minced meat and proofing. Cheesecakes are baked at 230-240 °C for 6-8 minutes.

Pancakes with minced meat. Add salt, sugar, eggs to milk or water, add flour, knead the batter and strain. Pancakes are baked in greased and heated frying pans 24-26 cm in size. The pancakes are fried on one side, then minced meat is placed on the fried side, wrapped, giving the product the shape of a flat pie, and fried in the main way on both sides.

Minced meat. For stuffing dough products, minced meat, fish, potato, mushroom, rice, cottage cheese, and apple are used.

Quality requirement. The buns should be round and golden yellow to light brown in color; the surface is shiny, the dough is well baked.

The products should be round in shape with glossy edges, golden in color, and the dough should be well baked. The cake should be cylindrical in shape, without burnt places, the crumb should be yellow without “hardening”, non-sticky, the raisins should be evenly distributed in the dough, the top of the cake should be sprinkled with powdered sugar. Pie "Moscow" The sides of the pie are shiny, light brown in color; The crumb is soft, porous, well baked, and springs when pressed.

Yeast dough is prepared in two ways - straight and sponged. The straight method of preparing dough includes one stage: preparation and fermentation of the dough. The dough is prepared using the straight method, mainly for products with a small amount of baked goods (sugar, butter, eggs) and a softer consistency. With this kneading method, the yeast rate is slightly increased compared to the yeast rate with the sponge method, since in thick dough the yeast multiplies more slowly.

Ingredients

- Wheat flour – 450 g

- Liquid (milk or water) – 1 cup

- Egg – 1 pc.

- Vegetable oil – 2 tbsp. spoons

- Sugar – 1 teaspoon

- Pressed yeast – 15 g

- or Dry yeast – 5 g

- Salt – ½ teaspoon

How to cook

First you need to “feed” the yeast. To do this, dissolve the yeast in 1/3 cup of warm water or milk, add 1 teaspoon of sugar and ½ cup of sifted flour.

Mix everything well until the consistency of sour cream and leave in a warm place for 20-25 minutes to increase in volume by 2-3 times (this way the quality of the yeast used is checked).

Then pour in the rest of the liquid, add the egg, salt, and add the remaining sifted flour. Knead the dough for 8-10 minutes, first in a bowl, and then on the table until a homogeneous, lump-free, not very stiff dough (if the specified amount of liquid is not enough, add a little milk or water).

At the end of kneading, return the dough to the bowl, add vegetable oil, and mix lightly.

Cover the bowl with the kneaded dough with a lid or tie it with a napkin and leave in a warm place for 1.5-2 hours to rise (the normal temperature for fermenting yeast dough is 28-30 degrees).

After the first rise (increasing the dough by 2-3 times), the dough should be kneaded. It is best to place the dough on a board sprinkled with flour and beat it well.

Then put it on the rise again for another 1-1.5 hours (the rise time is indicated approximately: the housewife herself must determine the readiness of the product for baking, since the rise of the dough depends on the temperature, type of flour, quality (freshness) of yeast, etc.) .

Why do you dream of eating red cherries?

Why do you dream of eating red cherries? Dream Interpretation. avalanche - all interpretations. Dream Interpretation avalanche, what does it mean to dream about an avalanche?

Dream Interpretation. avalanche - all interpretations. Dream Interpretation avalanche, what does it mean to dream about an avalanche? Why do you dream of a callus on the heel - interpretation of sleep from dream books

Why do you dream of a callus on the heel - interpretation of sleep from dream books Speech consists of sentences

Speech consists of sentences Construction company LEGENDA Intelligent Development Residential complex on Institutsky Avenue 16

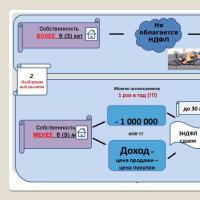

Construction company LEGENDA Intelligent Development Residential complex on Institutsky Avenue 16 What are the tax deductions for selling real estate?

What are the tax deductions for selling real estate? Georgy Sidorov - the radiance of the highest gods and the rocks

Georgy Sidorov - the radiance of the highest gods and the rocks